The Importance Of A Quality Mould Base In Manufacturing Processes

Are you looking to improve your manufacturing processes and produce higher quality products? Look no further than the importance of a quality mould base. In this article, we will explore the crucial role a mould base plays in the manufacturing industry and how investing in a high-quality mould base can significantly impact the overall production process. Whether you are a seasoned manufacturer or just starting out, understanding the significance of a quality mould base is essential for achieving optimal results. Read on to discover the key factors that make a quality mould base indispensable in the manufacturing world.

- Understanding the Role of Mould Bases in Manufacturing

Understanding the Role of Mould Bases in Manufacturing

When it comes to manufacturing processes, the quality of the mould base plays a crucial role in ensuring the overall success of a project. Mould bases are the foundation upon which moulds are built, and they serve as the backbone of the entire manufacturing process. Understanding the role of mould bases in manufacturing is essential for anyone involved in the industry, as it can have a significant impact on the final product's quality, cost, and lead time.

To understand the importance of a quality mould base, it is essential to first consider the function it serves in the manufacturing process. Mould bases provide a stable and rigid platform on which the mould is mounted, ensuring that it remains in the proper position throughout the manufacturing process. This stability is crucial for producing consistent and accurate parts, as any movement or shift in the mould can result in defects or inconsistencies in the finished product. Additionally, the quality of the mould base can impact the overall durability and lifespan of the mould, as a high-quality base can withstand the rigors of the manufacturing process and prolonged use.

One of the key benefits of using a quality mould base is the improved efficiency and lead time in the manufacturing process. A well-constructed mould base allows for faster and more precise mould alignment, reducing the time and effort required for setup and adjustments. This can lead to increased productivity and cost savings for manufacturers, as they are able to produce parts more quickly and with fewer errors. Additionally, the use of a quality mould base can also result in reduced maintenance and downtime, as it can withstand the wear and tear of repeated use without the need for frequent repairs or replacements.

Furthermore, the use of a quality mould base can have a significant impact on the overall quality of the finished product. A stable and precise mould base ensures that the mould remains in the correct position during the manufacturing process, resulting in parts that meet or exceed the required specifications. This level of consistency and accuracy is crucial for manufacturers, as it can help to reduce waste, rework, and scrap, ultimately leading to cost savings and improved customer satisfaction. Additionally, the durability of a quality mould base can also contribute to the overall quality of the product, as it can help to prevent issues such as warping, flashing, or other defects that can result from a poorly constructed or unstable base.

In conclusion, the role of mould bases in manufacturing cannot be overstated. A quality mould base is essential for ensuring the stability, efficiency, and overall quality of the manufacturing process. By understanding the importance of a quality mould base, manufacturers can make informed decisions about their tooling needs, ultimately leading to improved productivity, cost savings, and a higher quality finished product.

- Key Characteristics of a Quality Mould Base

The mould base is an essential component in the manufacturing industry, particularly in the production of plastic and metal parts. It serves as the foundation for the mould, providing the necessary support and alignment for the creation of high-quality parts. A quality mould base is crucial for the success of any manufacturing process, as it directly impacts the accuracy, durability, and efficiency of the moulding operation.

There are several key characteristics that define a quality mould base. These characteristics play a vital role in ensuring the overall performance and longevity of the mould base, as well as the parts being produced. Understanding these key characteristics is essential for manufacturers who are looking to improve their moulding processes and produce top-quality parts consistently.

Precision and Accuracy

One of the most important characteristics of a quality mould base is precision and accuracy. The mould base must be precisely manufactured to exact specifications, ensuring that it provides the necessary support and alignment for the mould. Any deviation from the specified dimensions can lead to defects in the parts being produced, resulting in waste and inefficiency in the manufacturing process.

Material Quality

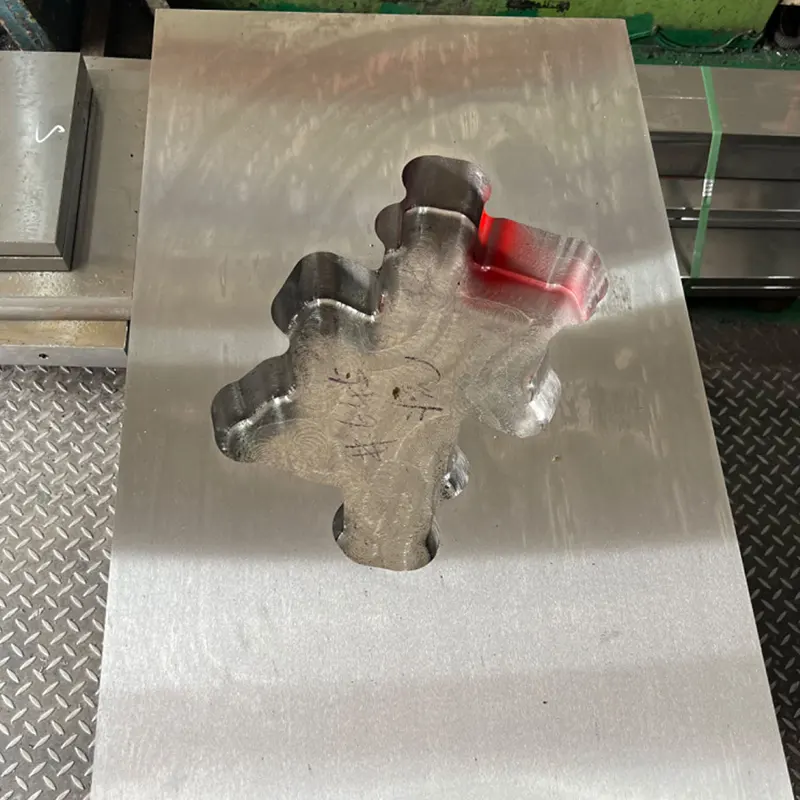

The material used in the construction of the mould base is another critical characteristic. A high-quality mould base should be made from durable materials that can withstand the rigors of the moulding process. Common materials used for mould bases include steel, aluminum, and pre-hardened steel. These materials offer the necessary strength and durability to ensure the longevity and performance of the mould base.

Surface Finish and Coating

The surface finish of the mould base is also important, as it directly impacts the quality of the parts being produced. A smooth and uniform surface finish is essential for facilitating the ejection of parts from the mould, as well as preventing defects such as flashing or sink marks. Additionally, the use of coatings such as nitriding or chrome plating can further enhance the durability and performance of the mould base, providing protection against wear and corrosion.

Compatibility and Interchangeability

A quality mould base should also be designed for compatibility and interchangeability with other components of the moulding operation. This allows for the efficient use of standard components and tooling, as well as the ability to interchange mould bases for different parts and production requirements. The ability to easily change mould bases can greatly improve the flexibility and efficiency of the manufacturing process.

Overall Design and Construction

The overall design and construction of the mould base are crucial for its performance and longevity. A quality mould base should be designed with proper cooling and ejection systems, as well as provisions for mounting the mould and auxiliary equipment. The construction should be robust and rigid, with proper alignment and support for the mould components. Additionally, attention should be given to factors such as weight, size, and ease of handling to ensure the practicality and usability of the mould base.

In conclusion, the importance of a quality mould base in manufacturing processes cannot be overstated. The key characteristics of precision and accuracy, material quality, surface finish and coating, compatibility and interchangeability, and overall design and construction are essential for ensuring the performance and longevity of the mould base. By understanding and prioritizing these characteristics, manufacturers can improve their moulding processes and consistently produce high-quality parts.

- Impact of Mould Base Quality on Manufacturing Efficiency

Mould bases serve as the foundation for creating a wide range of products, from plastic parts to metal components. The impact of mould base quality on manufacturing efficiency cannot be overstated, as it affects everything from the accuracy and consistency of the final products to the overall productivity of the manufacturing process.

When it comes to manufacturing, time is money. Any delay or disruption in the production process can result in significant financial losses. This is where the quality of the mould base comes into play. A high-quality mould base provides a solid and reliable platform for the creation of intricate and precise components, which in turn, directly impacts manufacturing efficiency.

The quality of the mould base can affect manufacturing efficiency in several ways. Firstly, a high-quality mould base ensures dimensional accuracy and uniformity in the parts being manufactured. This reduces the need for rework or adjustments, saving time and resources in the production process.

Additionally, a quality mould base provides stability and durability, which is essential for maintaining consistency in the manufacturing process. It also helps prevent issues such as warping, distortion, and premature wear, which can lead to production delays and increased costs.

Furthermore, a well-designed and well-crafted mould base facilitates smooth operation and maintenance of the moulding equipment. This not only minimizes downtime but also enhances the overall productivity of the manufacturing process.

In summary, the impact of mould base quality on manufacturing efficiency is multi-faceted. It directly influences the accuracy, consistency, and productivity of the production process. Therefore, investing in high-quality mould bases is crucial for manufacturers looking to streamline their operations and optimize their output.

From a financial standpoint, the upfront cost of quality mould bases may seem daunting. However, the long-term benefits far outweigh the initial investment. High-quality mould bases not only contribute to improved manufacturing efficiency but also result in higher-quality products and ultimately, greater customer satisfaction.

In conclusion, the importance of a quality mould base in manufacturing processes cannot be emphasized enough. It is a foundational element that directly impacts the efficiency and overall success of the production process. By prioritizing the use of high-quality mould bases, manufacturers can optimize their operations, reduce costs, and ultimately, achieve greater success in the marketplace.

- Importance of Precision and Durability in Mould Bases

When it comes to manufacturing processes, the importance of a quality mould base cannot be overstated. In particular, precision and durability are two key factors that can make or break a manufacturing operation. The mould base serves as the foundation for the entire moulding process, providing the necessary support and stability for the mould cavity and core. Without a quality mould base, the entire manufacturing process is at risk of compromising the integrity and precision of the final product.

Precision is perhaps the most critical aspect of a quality mould base. The dimensions of the mould base must be meticulously calculated and constructed to ensure that the final product meets the exact specifications required by the manufacturing process. Any deviation in the dimensions of the mould base can lead to defects in the final product, resulting in wasted materials and resources. Furthermore, the precision of the mould base directly impacts the overall efficiency of the manufacturing process, as any inaccuracies can lead to costly adjustments and delays.

In addition to precision, durability is equally important in a quality mould base. The mould base must be able to withstand the rigors of the moulding process, which often involves high temperatures, pressure, and mechanical stress. A durable mould base not only ensures the integrity of the final product but also minimizes the need for frequent maintenance and replacement. This, in turn, reduces downtime and improves the overall efficiency and productivity of the manufacturing operation.

Furthermore, the choice of material for the mould base plays a crucial role in its durability. High-quality materials, such as tool steel or aluminum, are commonly used for their excellent wear resistance, thermal conductivity, and machinability. These materials not only enhance the durability of the mould base but also contribute to the precision of the final product. The use of inferior or substandard materials, on the other hand, can compromise the quality of the mould base and ultimately lead to costly repercussions for the manufacturing process.

Another important consideration in the design of a quality mould base is its ability to accommodate various moulding techniques and processes. Different manufacturing operations may require different types of mould base configurations, such as standard, custom, or modular bases. The flexibility and adaptability of the mould base to different moulding techniques and processes can significantly impact the overall efficiency and versatility of the manufacturing operation.

In conclusion, the importance of precision and durability in a quality mould base cannot be overstated. The mould base serves as the foundation for the entire moulding process, and any compromise in its precision or durability can have detrimental effects on the final product and the efficiency of the manufacturing operation. By prioritizing precision and durability in the design and construction of the mould base, manufacturers can ensure the integrity and quality of their products while optimizing the overall efficiency and productivity of their manufacturing processes.

- Investing in Quality Mould Bases for Long-Term Benefits

In the field of manufacturing, investing in a quality mould base is imperative for long-term success and sustainable benefits. A high-quality mould base is essential for producing durable and precise moulds, which ultimately contribute to the overall efficiency and quality of the manufacturing processes. In this article, we will delve into the importance of a quality mould base in manufacturing processes and explore the various benefits it offers.

A mould base serves as the foundation for the entire mould assembly. It provides support and stability to the mould components, ensuring that the mould remains intact and performs optimally during the manufacturing process. A quality mould base is manufactured using advanced technologies and high-grade materials, and it is designed to withstand the rigorous demands of industrial production. As such, investing in a quality mould base is crucial for ensuring the long-term viability and performance of the mould assembly.

One of the primary benefits of investing in a quality mould base is the assurance of precision and accuracy in the manufacturing processes. A well-constructed mould base provides the necessary structural integrity to maintain the dimensional stability and alignment of the mould components. This, in turn, enables the production of consistent and high-quality parts, leading to a reduction in production errors and waste. Additionally, a quality mould base allows for greater flexibility in design and customization, as it can accommodate complex geometries and intricate details with ease.

Furthermore, a quality mould base contributes to the overall efficiency of the manufacturing processes. By providing a solid and reliable foundation for the mould assembly, it minimizes the risk of downtime and maintenance, resulting in increased productivity and reduced production costs. Additionally, the durability and longevity of a quality mould base ensure a longer service life, translating to long-term cost savings and sustainability for manufacturers.

In addition to precision and efficiency, a quality mould base also plays a crucial role in ensuring the safety of the manufacturing processes. The stability and reliability of the mould base prevent potential hazards and accidents, thereby creating a safer working environment for operators and employees. This, in turn, contributes to overall operational excellence and compliance with industry regulations and standards.

It is important to emphasize that investing in a quality mould base is a strategic decision that has long-term benefits for manufacturers. While it may require a higher initial investment, the return on investment in terms of improved productivity, reduced costs, and enhanced product quality far outweighs the upfront costs. Moreover, a quality mould base acts as a solid foundation for future growth and expansion, providing manufacturers with a competitive edge in the market.

In conclusion, the importance of a quality mould base in manufacturing processes cannot be overstated. It serves as the cornerstone for precision, efficiency, and safety, ultimately contributing to the overall success and sustainability of manufacturing operations. Therefore, manufacturers should prioritize the investment in high-quality mould bases to secure long-term benefits and competitive advantages in the industry.

Conclusion

In conclusion, the importance of a quality mould base in manufacturing processes cannot be overstated. As a company with 18 years of experience in the industry, we have seen first-hand the impact that a well-crafted mould base can have on the quality and efficiency of a manufacturing process. Investing in a high-quality mould base not only ensures the production of consistent, high-quality products, but also reduces the risk of costly delays and repairs. It is clear that a quality mould base is a critical component of any successful manufacturing operation, and we are committed to providing our clients with the best possible solutions to meet their needs.