Understanding The Importance Of Mould Base Plates In Manufacturing

Welcome to our article on the importance of mould base plates in manufacturing. Mould base plates are a critical component in the production of a wide range of products, and understanding their significance is key to achieving high quality and efficient manufacturing processes. In this article, we will delve into the reasons why mould base plates are essential, explore their impact on the manufacturing industry, and provide insights into how they contribute to the overall production process. Whether you are a seasoned professional in the manufacturing industry or just beginning to explore the world of manufacturing, this article will provide valuable information on the importance of mould base plates. So, let’s dive in and discover the key role that mould base plates play in shaping the manufacturing landscape.

- Introduction to Mould Base Plates

to Mould Base Plates

Mould base plates are an essential component in the manufacturing industry, especially in the production of plastic and metal parts. These plates serve as the foundation for the moulding process, providing a stable and rigid platform for the mould to be mounted on. Understanding the importance of mould base plates in manufacturing is crucial for ensuring the quality and efficiency of the production process.

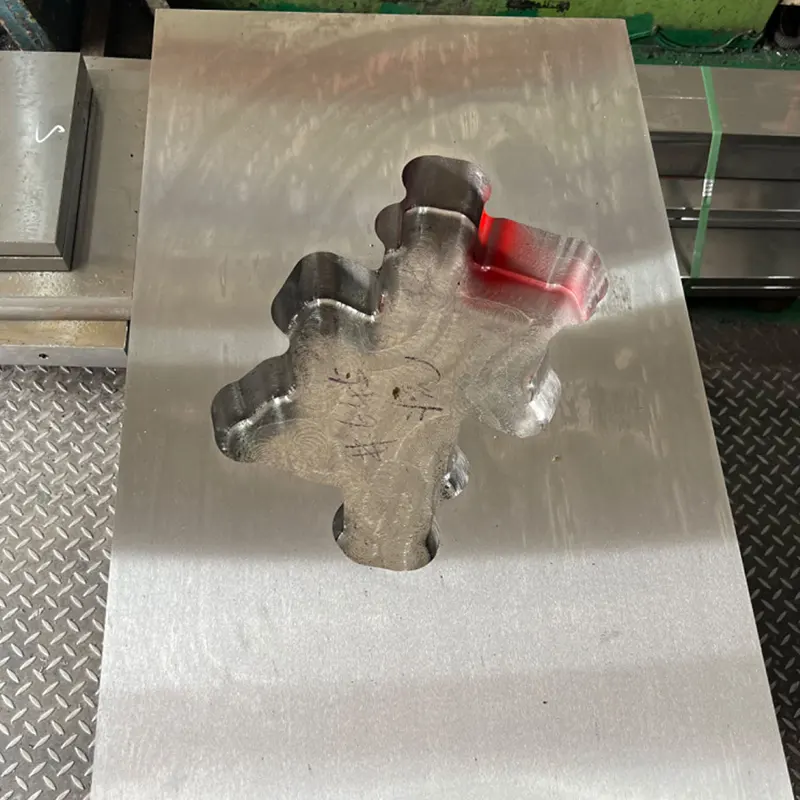

Mould base plates are typically made from high-quality materials such as steel or aluminum, which are chosen for their strength, durability, and resistance to wear and tear. These plates are precision-machined to tight tolerances to ensure that they provide a flat and even surface for the mould to sit on. This level of precision is crucial for the production of high-quality parts, as any deviations in the flatness of the mould base plate can result in defects in the finished products.

The primary function of mould base plates is to support the mould and provide a stable platform for the injection or compression process. This ensures that the mould remains in the correct position throughout the production cycle, preventing any movements or shifts that could result in production errors. Additionally, the rigidity of the mould base plate helps to absorb and distribute the forces and pressures exerted during the moulding process, further ensuring the integrity of the production process.

Mould base plates also play a critical role in the alignment and assembly of the mould components. The precise machining of the base plate allows for accurate positioning of the mould halves, inserts, and other components, ensuring that they fit together seamlessly and maintain the necessary dimensional tolerances. This level of precision is essential for achieving consistent and accurate part dimensions, which is crucial in many manufacturing applications.

In addition to providing a stable foundation for the mould, base plates also act as a heat sink, helping to dissipate the heat generated during the moulding process. This is particularly important in high-temperature applications, such as injection moulding, where maintaining the proper temperature is crucial for the quality of the finished parts. The ability of the mould base plate to absorb and dissipate heat helps to ensure that the moulding process remains stable and consistent, further contributing to the overall quality of the production.

Furthermore, mould base plates also play a crucial role in the maintenance and serviceability of the mould. By providing a stable and secure mounting platform for the mould, base plates make it easier to remove, inspect, and replace mould components as needed. This is essential for routine maintenance, repairs, and modifications, allowing manufacturers to quickly and efficiently address any issues that may arise during the production process.

In conclusion, mould base plates are a fundamental component in the manufacturing industry, serving as the foundation for the moulding process and playing a crucial role in the quality and efficiency of production. Their precision-machined construction, stability, and heat-dissipating properties all contribute to the overall integrity of the moulding process, making them a vital component in modern manufacturing operations. Understanding the importance of mould base plates in manufacturing is essential for ensuring the consistent production of high-quality parts.

- The Role of Mould Base Plates in Manufacturing

Mould base plates play a crucial role in the manufacturing industry, providing a solid foundation for the production of various plastic and metal components. From injection molding to die casting, these plates are essential for ensuring the accuracy, precision, and efficiency of the manufacturing process. In this article, we will delve into the importance of mould base plates in manufacturing and explore their role in producing high-quality products.

First and foremost, mould base plates serve as the structural support for the mould cavity and core. They provide a stable platform for the entire mould assembly, allowing for the precise alignment of the various components. This is particularly important in injection molding, where the mould base plates must withstand significant pressure and force during the injection process. Without a sturdy and durable base plate, the mould assembly would be prone to misalignment, leading to defective parts and production delays.

In addition to providing structural support, mould base plates also contribute to the overall accuracy and precision of the manufacturing process. The flatness and parallelism of the base plate are critical for ensuring uniform wall thickness and consistent part dimensions. Any deviation in the flatness of the base plate can result in imperfections in the final product, leading to quality issues and rework. Therefore, manufacturers must pay close attention to the quality and precision of the mould base plates to maintain the integrity of the production process.

Furthermore, mould base plates play a vital role in the efficient and cost-effective production of parts. By providing a stable and reliable foundation for the mould assembly, these plates help minimize downtime and optimize the production cycle. They also enable quick and easy tool changes, allowing manufacturers to adapt to changing production demands and reduce lead times. In this way, mould base plates contribute to the overall productivity and competitiveness of manufacturing operations.

Moreover, the material selection and manufacturing process of mould base plates are crucial factors in their performance and longevity. High-quality materials, such as tool steel or aluminum, are often used to ensure the durability and stability of the base plates. Additionally, advanced machining techniques, such as CNC milling and grinding, are employed to achieve the required flatness and precision of the plates. These factors are essential for meeting the rigorous demands of modern manufacturing processes and ensuring the reliability of the mould base plates.

In conclusion, mould base plates are an essential component in the manufacturing industry, providing the structural support, accuracy, and efficiency needed for the production of high-quality parts. Their role in ensuring the precision and stability of the mould assembly cannot be overstated, and manufacturers must prioritize the quality and performance of these critical components. By understanding the importance of mould base plates in manufacturing, companies can optimize their production processes and achieve superior results in today's competitive market.

- Benefits of Using Mould Base Plates

Mould base plates play a crucial role in the manufacturing industry, serving as the foundation for various machining and tooling processes. These plates are essential components in the production of plastic and metal parts, as they provide a stable and reliable platform for moulds and dies. In this article, we will explore the numerous benefits of using mould base plates in manufacturing, and how they contribute to the overall efficiency and quality of the production process.

One of the key advantages of using mould base plates is their ability to ensure precision and accuracy in the manufacturing process. These plates are machined to very tight tolerances, providing a flat and level surface for the mould or die to be mounted on. This level of precision is critical in achieving uniform and consistent part production, as any deviations in the mould base plate could result in faulty or defective parts. By using mould base plates, manufacturers can be confident in the quality and reliability of their products.

Another important benefit of mould base plates is their versatility and adaptability to different manufacturing needs. These plates come in a variety of sizes, shapes, and materials, allowing for customization to suit specific production requirements. Whether it's a large-scale industrial operation or a small-scale custom fabrication, mould base plates can be tailored to fit the unique needs of any manufacturing process. This level of flexibility is invaluable in ensuring that the production environment is optimized for efficiency and productivity.

In addition to precision and versatility, mould base plates also offer durability and longevity. Made from high-quality materials such as steel or aluminum, these plates are designed to withstand the rigors of heavy-duty machining and tooling operations. Their robust construction ensures that they can withstand constant use and frequent mold changes without compromising their structural integrity. This durability translates to long-term cost savings for manufacturers, as they can rely on the longevity of their mould base plates to minimize replacement and maintenance costs.

Furthermore, mould base plates contribute to the overall safety and stability of the manufacturing process. With a secure and stable base, the risk of accidents or mishaps during machining and tooling operations is significantly reduced. Workers can have peace of mind knowing that the moulds and dies are securely mounted on a reliable platform, minimizing the potential for damage, injury, or downtime. This emphasis on safety not only benefits the workers but also ensures a smooth and uninterrupted production flow.

In conclusion, the use of mould base plates is an integral part of the manufacturing process, offering a wide range of benefits that contribute to the overall efficiency, quality, and safety of production operations. By providing precision, versatility, durability, and stability, these plates play a vital role in ensuring that manufacturers can meet their production goals while maintaining high standards of quality and reliability. As the manufacturing industry continues to evolve, the significance of mould base plates will remain a constant factor in driving success and innovation.

- Factors to Consider When Selecting Mould Base Plates

Mould base plates play a crucial role in the manufacturing industry, as they provide the foundation for creating high-quality products. When selecting mould base plates, there are several factors to consider in order to ensure optimal performance and efficiency. Understanding these factors is essential for manufacturers to make informed decisions and achieve the best results in their production processes.

One of the most important factors to consider when selecting mould base plates is the material used in their construction. The material must be durable, heat-resistant, and able to withstand the pressures and strains of the manufacturing process. Common materials for mould base plates include steel, aluminum, and pre-hardened steel. Steel is known for its high tensile strength and excellent wear resistance, making it a popular choice for mould base plates. Aluminum, on the other hand, is lighter in weight and offers good thermal conductivity, making it suitable for certain applications. Pre-hardened steel is another option that provides high hardness and good machinability, ideal for achieving precise molds for manufacturing.

In addition to material, the size and dimensions of the mould base plates are also crucial considerations. The plates must be selected to fit the specific requirements of the intended manufacturing process and the size of the mold being used. The accuracy and precision of the dimensions are essential for ensuring that the final product meets the desired specifications. It is important to carefully measure and evaluate the dimensions of the mold to ensure a proper fit with the selected base plates.

The design and layout of the mould base plates are also important factors to consider. The plates must be designed to accommodate the various components of the mold, including the cavity, core, and other inserts. The design should also allow for proper cooling and ejection of the molded parts. A well-thought-out design will contribute to efficient production processes and consistent quality of the finished products.

Furthermore, the surface finish of the mould base plates is a critical consideration. The finish must be smooth and free from any defects or imperfections to ensure high-quality and accurate molding. A smooth surface finish will also facilitate the release of the finished parts from the mold, reducing the risk of defects and improving the overall efficiency of the manufacturing process.

Another important factor to consider is the cost and lead time of the mould base plates. Manufacturers must weigh the cost of the plates against the benefits they offer in terms of performance, durability, and quality. It is also important to consider the lead time for the production and delivery of the plates, as this can impact the overall timeline of the manufacturing process.

In conclusion, the selection of mould base plates is a critical decision that can have a significant impact on the quality and efficiency of the manufacturing process. By considering factors such as material, size, design, surface finish, and cost, manufacturers can make informed choices that will contribute to the success of their production processes. With careful consideration and attention to detail, manufacturers can ensure that their mould base plates meet the specific requirements of their manufacturing operations, leading to high-quality and consistent products.

- Innovations in Mould Base Plate Technology

Mould base plates are an essential component in the manufacturing industry, providing a foundation for moulds used in the production of various products. These plates are crucial for ensuring the accuracy and efficiency of the moulding process. In recent years, there have been significant innovations in mould base plate technology, leading to improvements in manufacturing processes and overall product quality.

One of the key innovations in mould base plate technology is the use of advanced materials. Traditionally, mould base plates were made of steel, but recent advancements have led to the development of high-strength, lightweight materials that offer improved durability and performance. These advanced materials not only provide greater stability and support for the mould, but also contribute to the overall efficiency of the manufacturing process.

Furthermore, advancements in CNC machining technology have revolutionized the manufacturing of mould base plates. CNC machining allows for the precise and complex shaping of mould base plates, ensuring a perfect fit for the mould and enhancing the overall quality of the end product. This level of precision and accuracy would have been difficult to achieve using traditional manufacturing methods.

In addition to material and machining advancements, innovations in mould base plate technology have also focused on improving the design and construction of these plates. Modern mould base plates are designed to accommodate various types of moulds and are customizable to meet the specific requirements of different manufacturing processes. This flexibility and adaptability are crucial in today's fast-paced manufacturing environment, where companies are constantly seeking ways to enhance productivity and efficiency.

Another area of innovation in mould base plate technology is the integration of smart features. Some mould base plates now come equipped with sensors and monitoring systems that provide real-time data on the performance and condition of the mould. This allows manufacturers to identify potential issues early on and make necessary adjustments to ensure optimal performance and product quality.

The advancements in mould base plate technology have also led to improvements in maintenance and servicing. Modern mould base plates are designed to be more accessible for maintenance and repairs, reducing downtime and improving the overall reliability of the manufacturing process. This has a direct impact on productivity and cost-effectiveness for manufacturers.

Overall, the innovations in mould base plate technology have significantly enhanced the manufacturing process, leading to cost savings, improved product quality, and greater efficiency. By incorporating advanced materials, CNC machining technology, smart features, and improved design and construction, manufacturers can benefit from a more reliable and adaptable moulding process.

In conclusion, the importance of mould base plates in manufacturing cannot be overstated, and the recent innovations in mould base plate technology have further solidified their role as a critical component in the production of high-quality products. As manufacturing processes continue to evolve, it is clear that mould base plate technology will play a crucial role in driving efficiency and innovation in the industry.

Conclusion

In conclusion, it is clear that mould base plates play a crucial role in the manufacturing industry. They provide the foundation for creating high-quality, precise, and consistent moulds, ultimately leading to better end products. As a company with 18 years of experience in the industry, we understand the significance of using top-quality mould base plates for our clients' projects. By prioritizing the importance of these components, we can ensure the success of our manufacturing processes and deliver exceptional results to our customers. With this understanding, we are committed to continuing to provide the highest quality mould base plates to support the success of our clients in the industry.