The Importance Of Choosing The Right Mould Base Plates For Your Manufacturing Process

Are you looking to optimize your manufacturing process and enhance the quality of your products? One crucial factor to consider is the selection of the right mould base plates. The choice of mould base plates can significantly impact the efficiency, accuracy, and overall success of the manufacturing process. In this article, we will explore the importance of choosing the right mould base plates and how it can positively impact your manufacturing operations. Whether you are a seasoned professional or new to the industry, this article will provide valuable insights into the crucial role of mould base plates in achieving manufacturing excellence.

Understanding the Role of Mould Base Plates in Manufacturing

When it comes to the manufacturing process, one of the key components that often goes overlooked is the role of mould base plates. These plates play a critical role in the production of a wide range of products across various industries, and understanding their importance is crucial for ensuring the success and efficiency of the manufacturing process.

Mould base plates, also known as mold base plates, are important components in the creation of molds for manufacturing. They provide the foundation for the mold, serving as a support structure for the various components that make up the mold. The quality and design of the mould base plates can have a significant impact on the overall quality and consistency of the final product.

One of the key roles of the mould base plates is to provide a stable and flat surface for the mold components to be assembled on. This is particularly important for ensuring that the mold produces consistent and high-quality products. Any imperfections or inconsistencies in the base plates can result in defects in the final product, leading to waste and inefficiency in the manufacturing process.

In addition to providing a stable foundation for the mold, the design of the mould base plates can also impact the overall efficiency of the manufacturing process. For example, the use of standardized base plate sizes and configurations can make it easier to interchange molds and components, allowing for greater flexibility and efficiency in the production process.

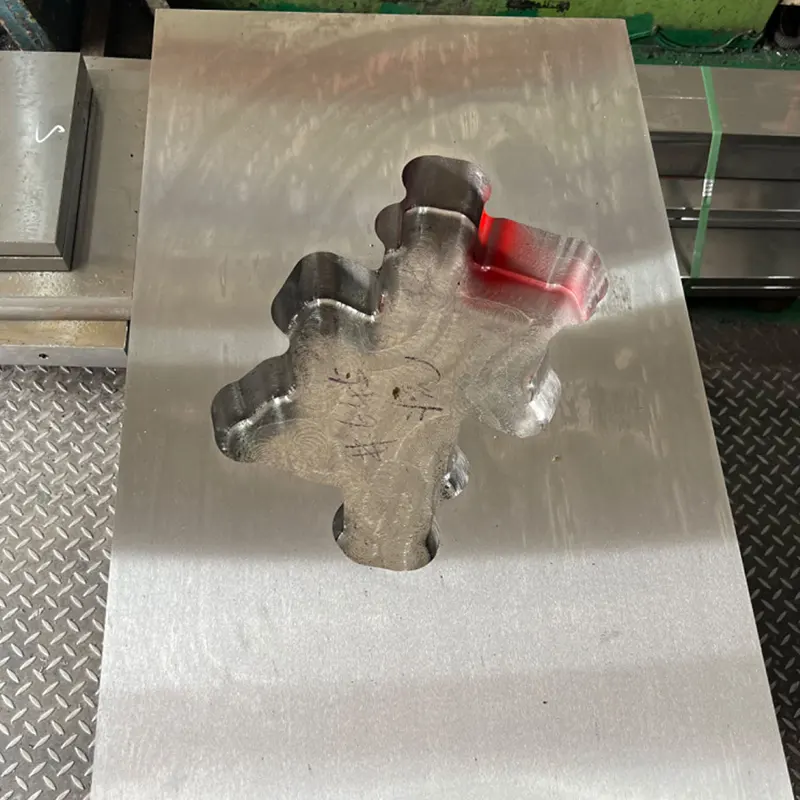

Furthermore, the material used in the construction of the mould base plates can also play a significant role in their performance. Materials such as steel and aluminum are commonly used due to their strength, durability, and resistance to wear and tear. These properties are particularly important in high-volume manufacturing environments where the molds are subjected to frequent use and potentially harsh conditions.

When choosing the right mould base plates for a manufacturing process, there are several factors that need to be taken into consideration. The specific requirements of the products being manufactured, the production volume, and the overall design of the molds are all important considerations that can impact the selection of the appropriate mould base plates.

In conclusion, the role of mould base plates in the manufacturing process is often overlooked, but their importance cannot be understated. These plates provide the foundation for the molds that are used to produce a wide range of products, and their quality and design can have a significant impact on the efficiency and consistency of the manufacturing process. By understanding the role of mould base plates and choosing the right ones for a specific manufacturing process, companies can ensure the success and efficiency of their production operations.

Factors to Consider When Choosing Mould Base Plates

Mould base plates are an essential component in the manufacturing process, and choosing the right ones can have a significant impact on the quality and efficiency of your production. There are several factors to consider when selecting mould base plates, and making the right choice can lead to improved productivity, reduced costs, and better overall results.

One of the most important factors to consider when choosing mould base plates is the material they are made from. The material used for mould base plates can have a significant impact on their performance and durability. For example, steel is a popular material for mould base plates due to its strength and heat resistance. It is important to consider the specific requirements of your manufacturing process when selecting the material for your mould base plates, as different materials may be more suitable for different applications.

In addition to the material, it is also important to consider the size and shape of the mould base plates. The size and shape of the mould base plates will depend on the specific requirements of your manufacturing process, and it is important to choose plates that are the right size and shape for your needs. A well-designed mould base plate can improve the accuracy and precision of your manufacturing process, leading to better results and reduced waste.

Another important factor to consider when choosing mould base plates is the cost. The cost of mould base plates can vary significantly depending on the material, size, and design. It is important to consider the overall cost of the mould base plates, including installation and maintenance, to ensure that they offer good value for money. While it may be tempting to opt for cheaper mould base plates to save money, it is important to consider the long-term costs and benefits of the plates to make an informed decision.

It is also important to consider the supplier when choosing mould base plates. The supplier of the mould base plates can have a significant impact on their quality and performance. It is important to choose a reputable and reliable supplier who can provide high-quality mould base plates that meet your specific requirements. Working with a trusted supplier can help ensure that you receive the best possible mould base plates for your manufacturing process.

Finally, it is important to consider the overall compatibility of the mould base plates with your manufacturing process. The mould base plates need to be compatible with the other components of your manufacturing process, including the moulds and machinery. It is important to consider the specific requirements of your manufacturing process to ensure that the mould base plates are a good fit and will function effectively.

In conclusion, choosing the right mould base plates is essential for the success of your manufacturing process. It is important to consider factors such as the material, size, shape, cost, supplier, and compatibility when selecting mould base plates. Making the right choice can lead to improved productivity, reduced costs, and better overall results for your manufacturing process.

Importance of Compatibility and Precision in Mould Base Plates

Mould base plates are an essential component in the manufacturing process, as they provide the foundation for creating high-quality and precise moulds. These plates are designed to hold the mould components in place and ensure that they are properly aligned during the manufacturing process. The importance of compatibility and precision in mould base plates cannot be overstated, as any deviation from these factors can result in defective products and costly rework.

Compatibility is a key factor when choosing mould base plates for your manufacturing process. The plates need to be compatible with the mould components and other equipment used in the manufacturing process to ensure seamless integration. Compatibility also extends to the material and design of the plates, as they need to be able to withstand the pressure and heat of the manufacturing process without warping or deforming.

Precision is equally important when it comes to mould base plates, as even the slightest deviation can result in defective products. The plates need to be precisely machined to ensure that the mould components are held in the correct position and alignment. This level of precision is crucial for producing high-quality products that meet the specifications and requirements of your customers.

When choosing mould base plates for your manufacturing process, it is important to consider the material of the plates. Steel is the most common material used for mould base plates, as it provides the necessary strength and durability to withstand the rigors of the manufacturing process. High-quality steel plates are also less likely to warp or deform, ensuring that the mould components remain in the correct position and alignment.

In addition to material, the design of the mould base plates is also a crucial factor to consider. The plates need to be designed in such a way that they provide ample support for the mould components and other equipment used in the manufacturing process. The design should also allow for easy installation and maintenance, as this can help reduce downtime and improve overall efficiency.

It is also important to consider the manufacturer of the mould base plates, as their expertise and experience can make a significant difference in the quality and performance of the plates. Working with a reputable and experienced manufacturer can provide you with access to high-quality mould base plates that are designed and engineered to meet the specific requirements of your manufacturing process.

In conclusion, the importance of compatibility and precision in mould base plates cannot be overstated. These plates provide the foundation for creating high-quality and precise moulds, and any deviation from these factors can result in defective products and costly rework. When choosing mould base plates for your manufacturing process, it is important to consider factors such as compatibility, precision, material, design, and the manufacturer to ensure that you are getting the best possible plates for your specific needs.

Impact of Mould Base Plate Selection on Production Efficiency and Quality

The choice of mould base plates plays a critical role in the efficiency and quality of the production process in manufacturing. In this article, we will explore the various factors that impact mould base plate selection and how it can significantly affect the overall production efficiency and quality.

The selection of mould base plates is a crucial decision in the manufacturing process. Mould base plates, also known as mold bases, are the foundation of any mold or die. They provide the support and stability necessary to produce high-quality and precise parts. The right mould base plate can ensure that the manufacturing process runs smoothly, efficiently, and yields products of the highest quality.

One of the key factors to consider when choosing mould base plates is the material. The material of the mould base plates can have a significant impact on the production process. For example, aluminum mould base plates are lightweight and provide excellent thermal conductivity, making them ideal for fast cycle times and reducing production costs. On the other hand, steel mould base plates are extremely durable and offer superior resistance to wear and tear, making them suitable for high-volume production runs. Selecting the appropriate material for the mould base plates can directly impact the production efficiency and the quality of the final products.

In addition to material, the design and construction of the mould base plates are also crucial in determining the production efficiency and quality. The design of the mould base plates should be tailored to the specific requirements of the manufacturing process, including the type of parts being produced, the complexity of the mold, and the production volume. A well-designed mould base plate can contribute to faster setup times, reduced downtime, and overall improved manufacturing efficiency. Moreover, the construction of the mould base plates, including the precision of machining and finishing, directly affects the quality and accuracy of the final products.

Furthermore, the compatibility of the mould base plates with the overall manufacturing system and equipment is another critical factor that influences production efficiency and quality. The mould base plates need to integrate seamlessly with other components of the mold and the manufacturing equipment. Poor compatibility can lead to production delays, increased scrap rates, and compromised product quality.

The impact of mould base plate selection on production efficiency and quality cannot be overstated. The right choice of material, design, construction, and compatibility can significantly improve the manufacturing process, resulting in higher productivity, reduced costs, and superior product quality. It is imperative for manufacturers to carefully consider these factors when selecting mould base plates to ensure optimal production performance.

In conclusion, the importance of choosing the right mould base plates for the manufacturing process cannot be emphasized enough. The impact of mould base plate selection on production efficiency and quality is substantial, and manufacturers must make informed decisions to ensure the success of their production operations. By carefully considering factors such as material, design, construction, and compatibility, manufacturers can maximize the efficiency and quality of their manufacturing process, ultimately leading to greater success and a competitive edge in the market.

Optimizing Your Manufacturing Process with the Right Mould Base Plates

Mould base plates are an integral part of any manufacturing process, as they serve as the foundation for creating high-quality, precision moulds for various products. In recent years, the importance of choosing the right mould base plates has become increasingly evident, as manufacturers seek to optimize their production processes and improve overall efficiency. This article explores the various factors that make choosing the right mould base plates crucial for the success of any manufacturing operation.

One of the key reasons that selecting the right mould base plates is so important is that they form the basis for the entire moulding process. The quality and durability of the base plates directly impact the performance and longevity of the moulds that are created using them. Choosing the wrong base plates can result in subpar mould quality, which can lead to defects in the final products, increased production time, and higher costs for reworking or scrapping faulty parts.

Additionally, the right mould base plates can significantly impact the overall efficiency of the manufacturing process. By selecting base plates that are durable, reliable, and suited to the specific needs of the production operation, manufacturers can reduce downtime, improve mould stability, and increase overall productivity. This is particularly crucial in high-volume production environments, where any improvements in efficiency can have a significant impact on the bottom line.

Another important consideration when choosing mould base plates is the materials and construction methods used in their fabrication. High-quality base plates should be made from materials that are capable of withstanding the demands of the moulding process, such as steel or aluminum. The construction of the base plates should also be carefully considered, as factors such as precision machining, flatness, and uniformity can all impact the quality and performance of the moulds they support.

Furthermore, the design and customization options available for mould base plates can also play a vital role in the success of a manufacturing process. Customized base plates can be tailored to the specific requirements of a particular moulding operation, allowing for greater flexibility and adaptability in the manufacturing process. This can be particularly beneficial for manufacturers that produce a wide variety of products or have unique moulding needs.

In conclusion, the importance of choosing the right mould base plates for a manufacturing process cannot be overstated. These components form the foundation for creating high-quality moulds and play a crucial role in optimizing production processes and improving overall efficiency. By carefully considering factors such as material, construction, and customization options, manufacturers can ensure that their mould base plates are up to the task of meeting the demands of their specific production operations. Ultimately, the right mould base plates can make a significant difference in the quality, efficiency, and success of a manufacturing process.

Conclusion

In conclusion, the importance of choosing the right mould base plates for your manufacturing process cannot be overstated. With 18 years of experience in the industry, we understand the critical role that mould base plates play in ensuring the success and efficiency of your manufacturing operations. By selecting the appropriate mould base plates for your specific needs, you can ensure the quality, accuracy, and durability of your products. At our company, we are committed to providing our customers with the highest quality mould base plates to help them achieve their production goals. Trust in our expertise and experience to guide you in making the right choice for your manufacturing process. Choose the right mould base plates, and take your production to the next level.