Plastic Mold Base Uppliers

Company Advantages

· The adoption of advanced technology gives Ruifengda plastic mold base a good surface finish.

· There are no lapses from a consistently high standard of manufacture.

· With years of exporting experience, Ruifengda Brand has quality assurance for plastic mold base.

|

Tolerance |

0.02mm-0.005mm |

Rust prevention measures |

Anti rust oil, anti rust spray, vacuum packaging... |

|

Mould life |

300000-500000 Shots |

Transaction mode |

FOB/CIF |

|

Major equipment |

YASDA, OKUMA |

Testing |

CMM, Opening and closing activities... |

|

Size |

Customer Size Accepted |

Supply ability | 300-400 sets per month |

|

Minimum order quantity |

1 Set |

Payment method |

T/T, Paypal, Cash |

|

Material Science |

S50C, P20, 1.2311, 718H, 4Cr13H, 420H, S136H ... |

OEM |

Available |

|

Packing |

Wooden box, plastic film |

Runner | Hot runner |

Mold plates

Now there are also some customers who do not order a single complete set of mold base, but only several mold plates. After receiving them, customers process and assemble them by themselves. This method can save a lot of time and shorten product delivery time.

In addition to customers ordering complete mold bases, there is also a growing demand for individual mold plates. This allows customers to process and assemble the plates themselves, ultimately saving time and reducing product delivery times. This flexibility enables customers to tailor their orders to their specific needs and further streamlines the manufacturing process. Additionally, by offering individual mold plates, we are able to cater to a wider range of customers and their unique requirements. This approach not only enhances customer satisfaction but also demonstrates our commitment to providing customized solutions.

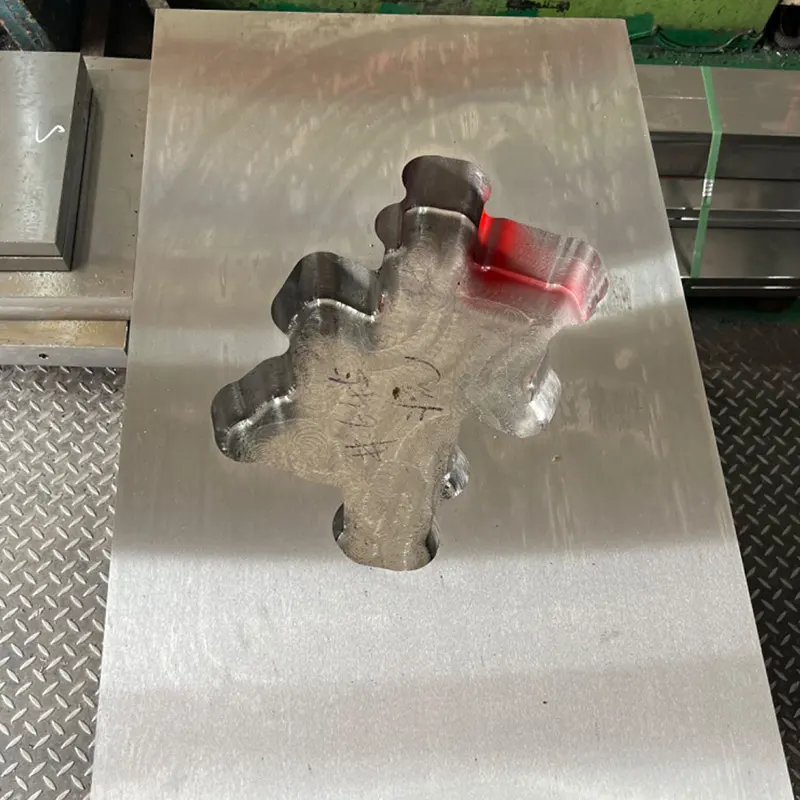

Rough processing

Process the rough shape. After roughening, there needs to be some margin left for subsequent precision machining.

After rough shaping, it is important to leave a margin for subsequent precision machining to ensure that the final product meets the required specifications and tolerances. This margin allows for any necessary adjustments and corrections to be made during the precision machining process, ultimately resulting in a high-quality and accurately dimensioned final product. By allowing for this margin, the rough shaping process sets the stage for the successful completion of the precision machining, ultimately contributing to the overall quality and precision of the final product.

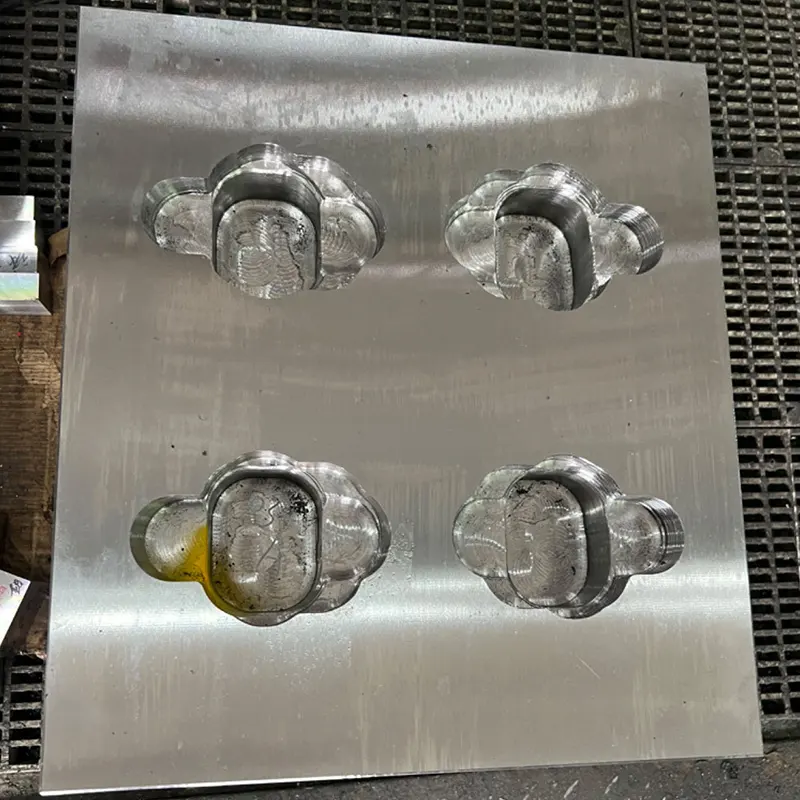

Cavity and core plates

The parallelism and verticality of the pocket must be controlled within 0.02mm. The length, width, and depth tolerance of the precision mould base should be 0~+0.02mm, and the thickness tolerance of the main plates should be ± 0.02mm. Precision machining is essential for screw holes, water line holes, ejector pin holes, nozzle holes, etc. All surfaces must be scratch-free, bright, and flat, and all chamfers must adhere to our company's standards and be uniform. Corresponding precision requirements will be established during the actual machining process based on specific mold design and customer needs.

Runner plate

The aperture and spacing of cavities play crucial roles in the manufacturing process. Precise dimensional tolerance is essential for the aperture to seamlessly fit with mating parts. A smooth surface, free of defects, is necessary to minimize friction and wear, ultimately extending the lifespan of the mold. Consistency in hole spacing within a multi-cavity mold base is vital for ensuring uniformity and stability. Following processing, rigorous CMM testing is carried out to verify the accuracy of the hole spacing.

fAQ

Company Features

· Ruifengda Brand is famous at home and abroad for manufacturing top quality of plastic mold base.

· We have established extensive business relations and formed a stable customer community in the USA, Canada, Australia, South Africa, and other countries, which makes our business boom.

· In order to satisfy users, we provide both high quality plastic mold base and first-rate service. Contact!

Application of the Product

The plastic mold base produced by Ruifengda is of high quality. And it is one of the products widely used in the industry.

We have a professional team and can provide customers with the most appropriate solutions to help customers achieve their goals quickly and effectively.

Product Comparison

Supported by advanced technology, Ruifengda has a great breakthrough in the comprehensive competitiveness of plastic mold base, as shown in the following aspects.

Enterprise Advantages

Ruifengda has an elite team with modern corporate quality, whose team members are clearly aware of their own duties. This guarantees the production to be efficient and products to be high-quality.

With a focus on service, Ruifengda provides comprehensive services for customers. Constantly improving service ability contributes to the sustainable development of our company.

Adhering to the core value, Ruifengda is courageous to challenge and make self-breakthrough. We also think highly of sincerity-based management and win-win cooperation. Competing in a decent way to make benefits is what we always believe in. We aim to meet customers' needs and market demand and strive to become a leading company in the industry.

Ruifengda, founded in has established a relatively scientific and effective safety management system.

Ruifengda's products occupy a certain market share in domestic and foreign regions.