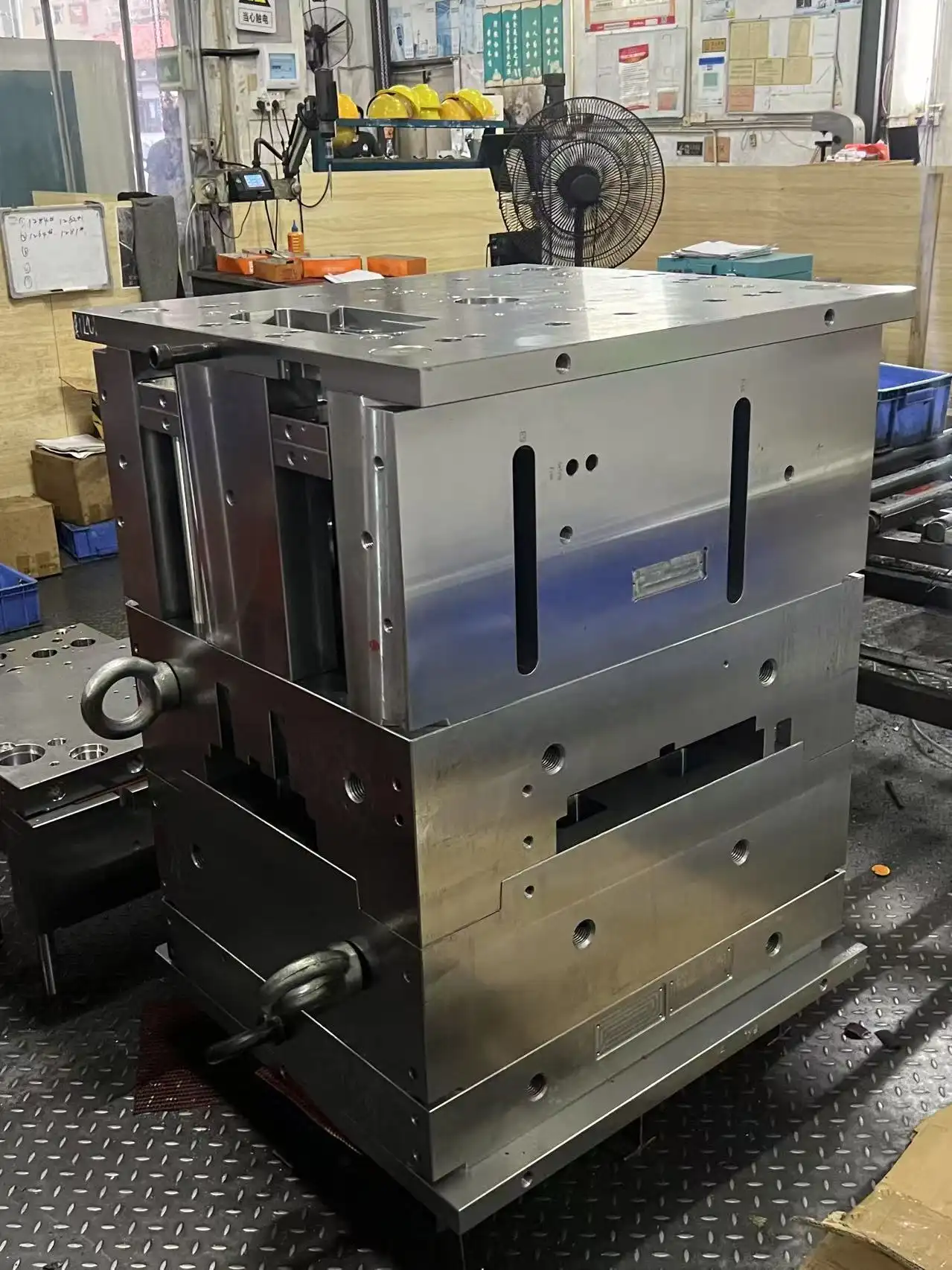

High precision customized mold base | Compatible with HASCO/DME standards | Supports complex structural design

At the core of our custom mold base service lies a commitment to innovation and collaboration. We work closely with clients to analyze tooling requirements, material flow dynamics, and operational constraints, delivering mold bases that exceed industry standards (DME, HASCO, or MISUMI specifications). Our offerings include non-standard sizes (up to 1500mm x 2500mm), specialized venting configurations, and lightweight alloys for energy-efficient production. With rigorous QA protocols and ISO 9001-certified processes, we guarantee mold bases that withstand high-pressure environments while maintaining <0.02mm flatness tolerance. Transform your vision into reality with agile, cost-effective solutions designed for tomorrow’s manufacturing challenges.

|

Tolerance |

0.02mm-0.005mm |

Rust prevention measures |

Anti rust oil, anti rust spray, vacuum packaging... |

|

Mould life |

300000-500000 Shots |

Transaction mode |

FOB/CIF |

|

Major equipment |

YASDA, OKUMA |

Testing |

CMM, Opening and closing activities... |

|

Size |

Customer Size Accepted |

Runner |

Hot runner |

|

Minimum order quantity |

1 Set |

Supply ability |

300-400 sets per month |

|

Material Science |

S50C, P20, 1.2311, 718H, 4Cr13H, 420H, S136H ... |

Payment method |

T/T, Paypal, Cash |

|

Packing |

Wooden box, plastic film |

OEM |

Available |

Customizable Accessories

From HASCO-compatible parts to specialized bronze components, our catalog covers both standard and custom mold base accessories. Whether you need self-lubricating bushings or bespoke ball cage systems, we tailor solutions to your exact requirements.

Ultra-Precision Mold Plates

Cavity and core plates are machined to exceptional standards: pocket dimensions controlled within +0.02mm, plate thickness held to ±0.02mm, and surfaces polished to a mirror finish. All features—including ejector pin holes and cooling channels—are precision-engineered for flawless mold performance.

Cutting-Edge CNC Technology

Our facility houses YASDA and OKUMA CNC machines, operating in a 22°C constant temperature workshop to minimize thermal expansion. Achieve tolerances as low as 0.003mm, even for large-scale molds up to 1500mm in length.

Rigorous Inspection Protocols

Using CMM systems, we validate every dimension and generate comprehensive reports to ensure compliance with your design. This meticulous approach eliminates defects and guarantees repeatable accuracy.

Shipping Protection

To combat corrosion during logistics, mold bases are treated with anti-rust coatings and wrapped in moisture-resistant film. Optional vacuum sealing provides extra protection for sensitive components.

fAQ

Precision mould base 0.01mm

Ultra-precision mould base 0.005mm