Mould Base Manufacturer Upply

Product details of the mould base manufacturer

Quick Detail

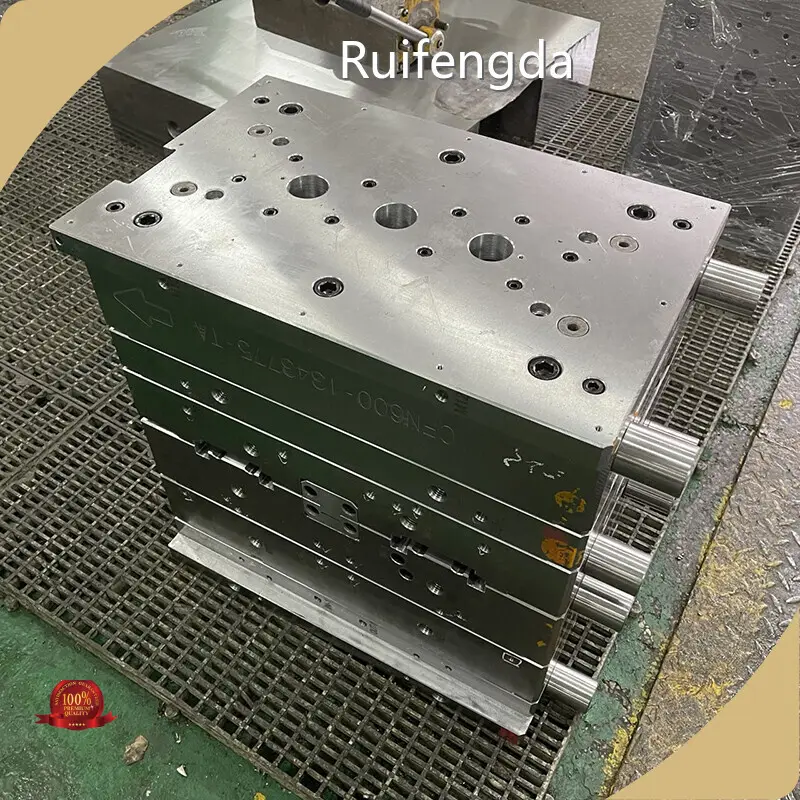

Ruifengda mould base manufacturer is fabricated with the aid of highly advanced machines. The rigorous testing procedures ensure that the product quality is consistently at its best. The mould base manufacturer developed by our company can play a role in various fields. Ruifengda Brand has established a complete sales network.

Product Introduction

Compared with the products in the market, the mould base manufacturer produced by our company has the following advantages.

|

Tolerance |

0.02mm-0.005mm |

Rust prevention measures |

Anti rust oil, anti rust spray, vacuum packaging... |

|

Mould life |

300000-500000 Shots |

Transaction mode |

FOB/CIF |

|

Major equipment |

YASDA, OKUMA |

Testing |

CMM, Opening and closing activities... |

|

Size |

Customer Size Accepted |

Runner |

Hot runner |

|

Minimum order quantity |

1 Set |

Supply ability |

300-400 sets per month |

|

Material Science |

S50C, P20, 1.2311, 718H, 4Cr13H, 420H, S136H ... |

Payment method |

T/T, Paypal, Cash |

|

Packing |

Wooden box, plastic film |

OEM |

Available |

Accessories

We provide an extensive selection of accessories for mold bases, including standard and nonstandard options such as HASCO, MISUMI, PUNCH, DME, and LKM. Furthermore, we have the capability to supply unique accessories like bronze parts, ball cage bushes, and self-lubricating components tailored to your exact specifications and needs.

Cavity and core plates

It is crucial to maintain precise control over the parallelism and verticality of the pocket within 0.02mm. The tolerance for the length, width, and depth of the precision mould base should be 0~+0.02mm, while the thickness tolerance of the main plates should be within ± 0.02mm. The precision machining of screw holes, water line holes, ejector pin holes, nozzle holes, and other features is imperative. All surfaces must be smooth, free from scratches, and have a uniform chamfer that adheres to our company's standards. During the actual machining process, specific precision requirements will be tailored to each mold design and the customer's needs.

CNC Machining

We are excited to present our extensive selection of high-precision CNC equipment from top brands such as YASDA and OKUMA, boasting over ten machines in our lineup. Our YASDA machines are utilized in a controlled environment at a consistent temperature of 22 ℃, delivering remarkable accuracy of 0.003mm and a machine travel of 900X1500X600mm. This guarantees that we can not only meet but surpass the high-precision needs of our discerning clientele.

Testing

We rely on CMM coordinate measurement to create accurate measurement reports. The precision of our measurements ensures that our products meet high quality and tolerance specifications.

Anti-corrosion treatment

In order to prevent rust on the mould base during shipping, we will take the necessary steps to ensure its protection. This includes applying anti-rust spray and oil to the surface of the mould base, and securely wrapping it with plastic film. If needed, we will also utilize vacuum packaging to further safeguard against rust. It is our priority to deliver the mould base in pristine condition, and we will take every precaution to ensure its safe and rust-free arrival.

fAQ

Company Introduction

Ruifengda Brand (Ruifengda) is a modern enterprise that insists on independent research and development, production and sales of mold base. With the service concept of 'customer first, service first', Ruifengda constantly improves the service and strive to provide professional, high-quality and comprehensive services for customers. We have strong strength and rich experience. And we are looking forward to discussing business cooperation with partners from all walks of life!