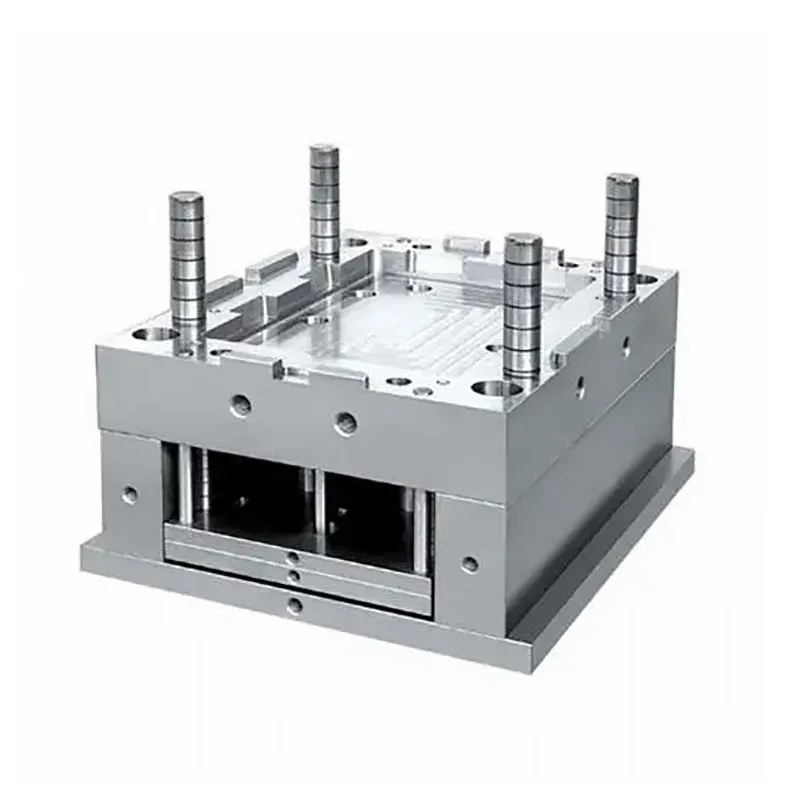

Mould Base Design - for Industrial - Ruifengda

Product details of the mould base design

Product Introduction

The production process of Ruifengda mould base design is regulated according to international standards. The material of mould base design enhances its performance and enhance its market competitiveness. Ruifengda established a comprehensive team to serve customers.

|

Tolerance |

0.02mm |

Rust prevention measures |

Anti rust oil, anti rust spray, vacuum packaging... |

|

Mould life |

300000-500000 Shots |

Transaction mode |

FOB/CIF |

|

Major equipment |

YASDA, OKUMA, CNC |

Testing |

CMM, Opening and closing activities... |

|

Size |

150*150mm to 600*800mm |

Supply ability | 300-400 sets per month |

|

Minimum order quantity |

1 Set |

Payment method |

T/T, Paypal, Cash |

|

Material Science |

S50C, P20, S136, NAK80 ... |

OEM |

Available |

|

Packing |

Wooden box, plastic film |

Materials and Customization

The standard material used for mold bases is S50C, with the option to use other materials for specific plates based on customer needs. Additionally, we can customize the standard mold base to meet the specific requirements of our customers.

Accessories

We offer a wide range of accessories for mould bases to meet your specific needs. Whether it's standard or nonstandard accessories, including HASCO, MISUMI, PUNCH, DME, and LKM, we've got you covered. Additionally, our capabilities extend to processing special accessories such as bronze components, ball cage bushings, and self-lubricating parts. Just provide us with the drawings and we will take care of the rest.

CNC Machining

We have a wide range of CNC equipment from top brands like YASDA and OKUMA to exceed the high-precision demands of our clients. For instance, our YASDA machines operate in a controlled temperature environment of 22 degrees Celsius, with an accuracy of 0.003mm and a machine travel of 900X1500X600mm.

Testing

We utilize CMM coordinate measurement and produce precise measurement reports. The high-precision measurements guarantee the quality and tolerance requirements of our products. By using the latest technology and equipment, we are able to consistently deliver products that meet and exceed customer expectations. Our commitment to accuracy and precision in our measurements enables us to identify and address any potential issues before they impact the final product. This proactive approach ultimately leads to cost savings and improved overall product performance. Our skilled and experienced team is dedicated to ensuring that every product that leaves our facility meets the highest standards of quality and precision.

Anti-corrosion treatment

To mitigate the effects of rust on the mould base during transportation, we will be applying anti-rust spray and anti-rust oil to the surface of the mould base. Following this, we will envelop them in plastic film and may resort to vacuum packaging if deemed necessary.

fAQ

Company Advantage

• The sales network of our products is spread all over the world.

• Our company has established an elite team of high-tech talents integrating product research and development and innovation.

• Our company persists in the principle of 'users are teachers, peers are examples'. We have a group of efficient and professional elite service personnel. Besides, we utilize scientific methods and advanced technology. Thus, we can provide our clients with super-quality services.

• Established in Ruifengda has a development history of years.

We always insist on the production of high-quality products. Welcome customers with needs to negotiate with us!