Injection Mould Base Upply-1

Product details of the injection mould base

Quick Detail

Ruifengda injection mould base is manufactured using high quality materials under the strict supervision of quality experts. The product is highly praised by experts regarding performance evaluation. Ruifengda's injection mould base can meet the different needs of customers. We are able to provide complete service system from pre sales to after sales.

Product Introduction

Under the premise of ensuring the same price, the injection mould base that we develop and produce as a whole has been substantially improved in a scientific way, as shown in the following aspects.

|

Tolerance |

0.02mm-0.005mm |

Rust prevention measures |

Anti rust oil, anti rust spray, vacuum packaging... |

|

Mould life |

300000-500000 Shots |

Transaction mode |

FOB/CIF |

|

Major equipment |

YASDA, OKUMA |

Testing |

CMM, Opening and closing activities... |

|

Size |

Customer Size Accepted |

Runner |

Hot runner |

|

Minimum order quantity |

1 Set |

Supply ability |

300-400 sets per month |

|

Material Science |

S50C, P20, 1.2311, 718H, 4Cr13H, 420H, S136H ... |

Payment method |

T/T, Paypal, Cash |

|

Packing |

Wooden box, plastic film |

OEM |

Available |

Accessories

All accessories of mould base can be provided according to the drawings. We can provide standard and nonstandard accessories such as HASCO, MISUMI, PUNCH, DME and LKM. Also, we process special accessories including bronze accessories, ball cage bush, self-lubricating parts, etc.

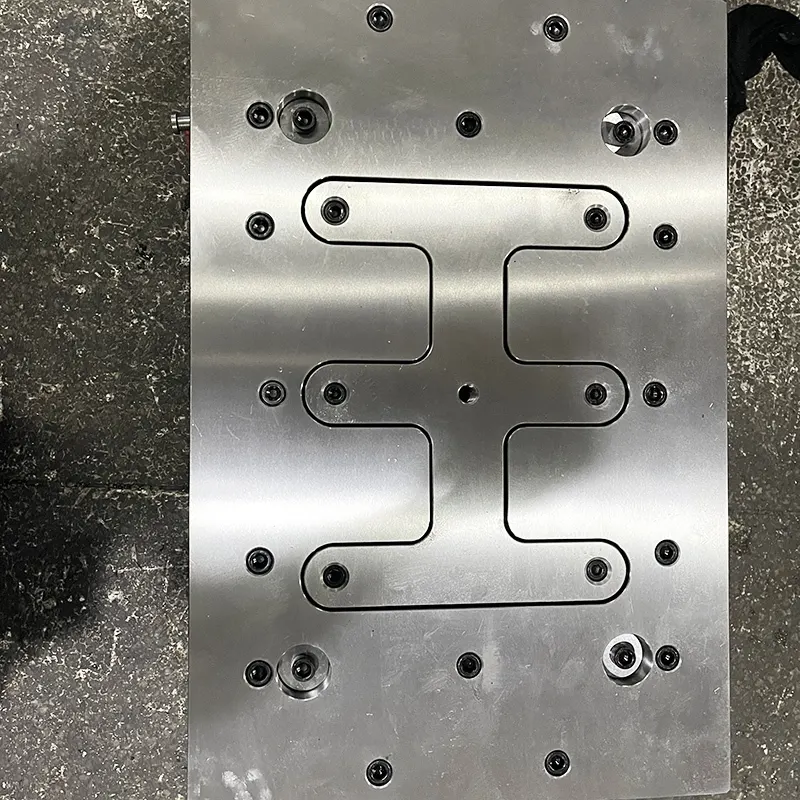

Cavity and core plates

The parallelism and verticality of pocket should be controlled within 0.02mm. The length, width, and depth tolerance of the precision mould base should be 0~+0.02mm, and the thickness tolerance of the main plates should be ± 0.02mm. Precision machining is required for screw holes, water line holes, ejector pin holes, nozzle holes, etc. All surfaces should be scratch free, bright and flat, all chamfers should comply with our company's standards and should be uniform. In the actual machining process, corresponding precision requirements will be formulated based on specific mold design and customer needs.

Runner plate

Aperture and spacing of cavities are important parts. The dimensional tolerance of the aperture is within a small range to ensure precise fit with the mating parts. The surface of the aperture is smooth, without scratches, burrs and other defects, which can reduce friction and wear, and improve the life of mold. In a multi cavity mould base, the hole spacing at the same position should be consistent, that is, the hole spacing between each cavity should be equal, which helps to ensure the uniformity and stability of all parts of the mold. After processing, we conduct strict CMM testing on the hole spacing.

Testing

We use CMM coordinate measurement and generate accurate measurement reports. Its high-precision measurement results can ensure product quality and tolerance requirements.

Anti-corrosion treatment

In order to reduce the impact of rust on mould base during shipping, we will use anti rust spray and anti rust oil on the surface of mould base, and then wrap them with plastic film. If necessary, vacuum packaging will be used.

fAQ

Company Information

Ruifengda Brand is an company located in shen zhen. Our main business is mold base production. Ruifengda is dedicated to serving customers and bringing value to them. We pay great attention to customers and exert ourselves to provide more quality products and more professional services. Ruifengda has a professional technical team, and regularly trains the team to improve their comprehensive strength. This provides technical support for R&D and production of products. Ruifengda insists on providing customers with comprehensive solutions based on their actual needs, so as to help them achieve long-term success.

We have been providing high quality injection mould base for a long time. We look forward to working with you.