High-quality Plastic Mould Base Price List

Company Advantages

· The deft design of plastic mould base has attracted more and more customers.

· The product has been approved by all required international certificates.

· This product is widely recognized in the market for its good economic benefits.

|

Tolerance |

0.02mm-0.005mm |

Rust prevention measures |

Anti rust oil, anti rust spray, vacuum packaging... |

|

Mould life |

300000-500000 Shots |

Transaction mode |

FOB/CIF |

|

Major equipment |

YASDA, OKUMA |

Testing |

CMM, Opening and closing activities... |

|

Size |

Customer Size Accepted |

Supply ability | 300-400 sets per month |

|

Minimum order quantity |

1 Set |

Payment method |

T/T, Paypal, Cash |

|

Material Science |

S50C, P20, 1.2311, 718H, 4Cr13H, 420H, S136H ... |

OEM |

Available |

|

Packing |

Wooden box, plastic film |

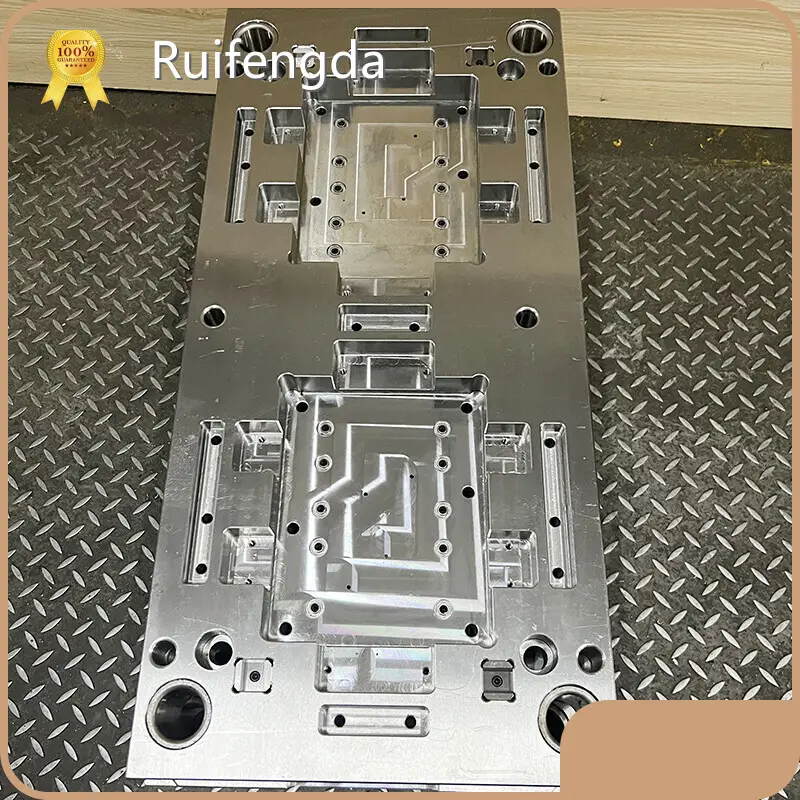

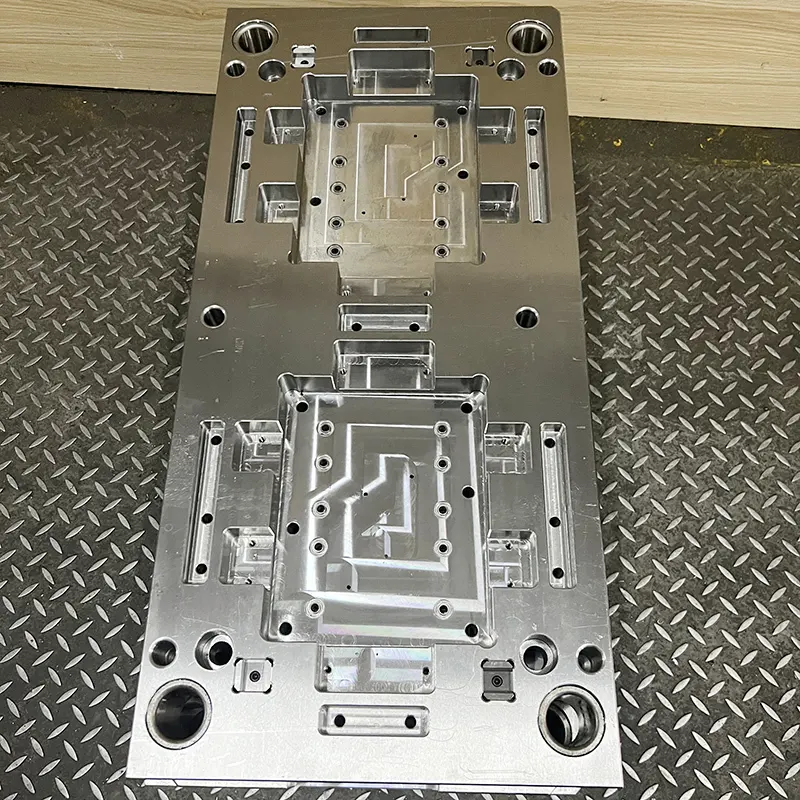

Mold plates

Now there are also some customers who do not order a single complete set of mold base, but only several mold plates. After receiving them, customers process and assemble them by themselves. This method can save a lot of time and shorten product delivery time.

Rough processing

Process the rough shape. After roughening, there needs to be some margin left for subsequent precision machining.

Cavity and core plates

The parallelism and verticality of pocket should be controlled within 0.02mm. The length, width, and depth tolerance of the precision mould base should be 0~+0.02mm, and the thickness tolerance of the main plates should be ± 0.02mm. Precision machining is required for screw holes, water line holes, ejector pin holes, nozzle holes, etc. All surfaces should be scratch free, bright and flat, all chamfers should comply with our company's standards and should be uniform. In the actual machining process, corresponding precision requirements will be formulated based on specific mold design and customer needs.

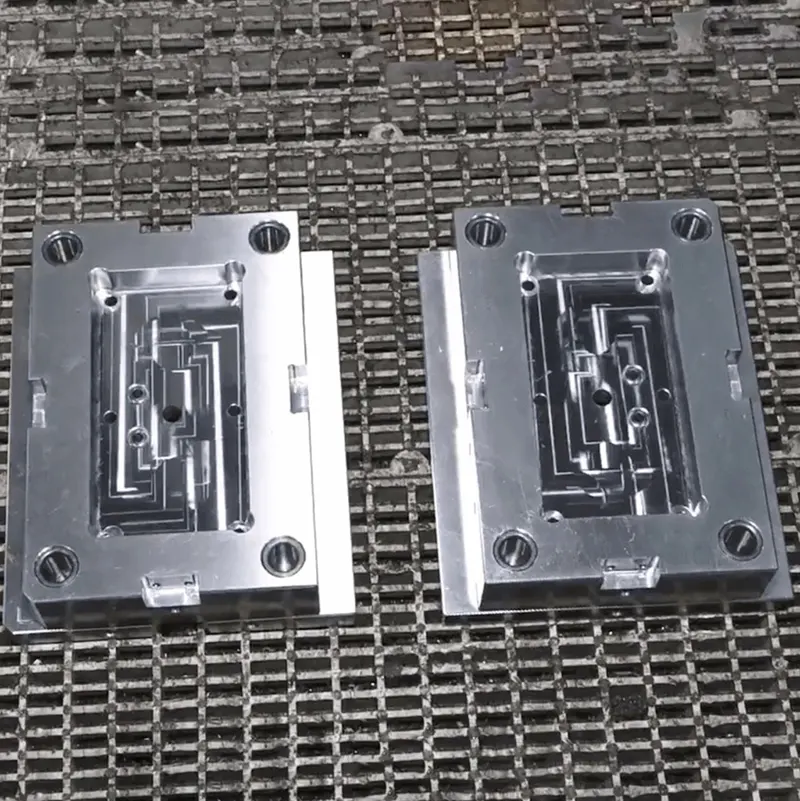

Runner plate

Aperture and spacing of cavities are important parts. The dimensional tolerance of the aperture is within a small range to ensure precise fit with the mating parts. The surface of the aperture is smooth, without scratches, burrs and other defects, which can reduce friction and wear, and improve the life of mold. In a multi cavity mould base, the hole spacing at the same position should be consistent, that is, the hole spacing between each cavity should be equal, which helps to ensure the uniformity and stability of all parts of the mold. After processing, we conduct strict CMM testing on the hole spacing.

fAQ

Company Features

· Ruifengda Brand pays attention to the plastic mould base and is influential in the business.

· With the globalization of supply chains, we are working with overseas partners. We have established corporate relationships with many customers, which enables us to grow steadily.

· Our company is based on a strong partnership approach - clients come first in every aspect of our decision-making. Get price!

Enterprise Advantages

Our company has a high-quality staff team. We are professional, efficient, pragmatic and aspirant. Our team members focus on their own duties and work hard to strive for excellence, making effort to produce high-quality bean products.

Ruifengda carries out strict checks and continuous improvement on customer service. We gain recognition from customers for the professional services.

Our company always insists on the business philosophy of 'credit first, integrity cooperation, mutual benefit and win-win', and we carry forward the enterprise spirit of 'pursuing excellence, willing to dedicate and advancing with the times'. Based on that, we provide quality products and services for consumers with professional team and efficient management.

After decades of struggle, Ruifengda now has a complete production chain.

Ruifengda's sales network continues to expand in China. The products are also exported to Central Asia, Eastern Europe, Northern Europe, and other regions.