High-quality Mold Base Manufacturers for Business for Industrial

Company Advantages

· Ruifengda mold base manufacturers is manufactured by our adroit professionals using premium grade raw material and modern technology.

· The additional functions of Ruifengda product deliver more economic benefits to customers.

· Ruifengda Brand has established mold base manufacturers business organizations in many regions, basically forming a strategic layout.

|

Tolerance |

0.02mm-0.005mm |

Rust prevention measures |

Anti rust oil, anti rust spray, vacuum packaging... |

|

Mould life |

300000-500000 Shots |

Transaction mode |

FOB/CIF |

|

Major equipment |

YASDA, OKUMA |

Testing |

CMM, Opening and closing activities... |

|

Size |

Customer Size Accepted |

Supply ability | 300-400 sets per month |

|

Minimum order quantity |

1 Set |

Payment method |

T/T, Paypal, Cash |

|

Material Science |

S50C, P20, 1.2311, 718H, 4Cr13H, 420H, S136H ... |

OEM |

Available |

|

Packing |

Wooden box, plastic film |

Runner | Hot runner |

Mold plates

Now there are also some customers who do not order a single complete set of mold base, but only several mold plates. After receiving them, customers process and assemble them by themselves. This method can save a lot of time and shorten product delivery time.

In addition to customers ordering complete mold bases, there is also a growing demand for individual mold plates. This allows customers to process and assemble the plates themselves, ultimately saving time and reducing product delivery times. This flexibility enables customers to tailor their orders to their specific needs and further streamlines the manufacturing process. Additionally, by offering individual mold plates, we are able to cater to a wider range of customers and their unique requirements. This approach not only enhances customer satisfaction but also demonstrates our commitment to providing customized solutions.

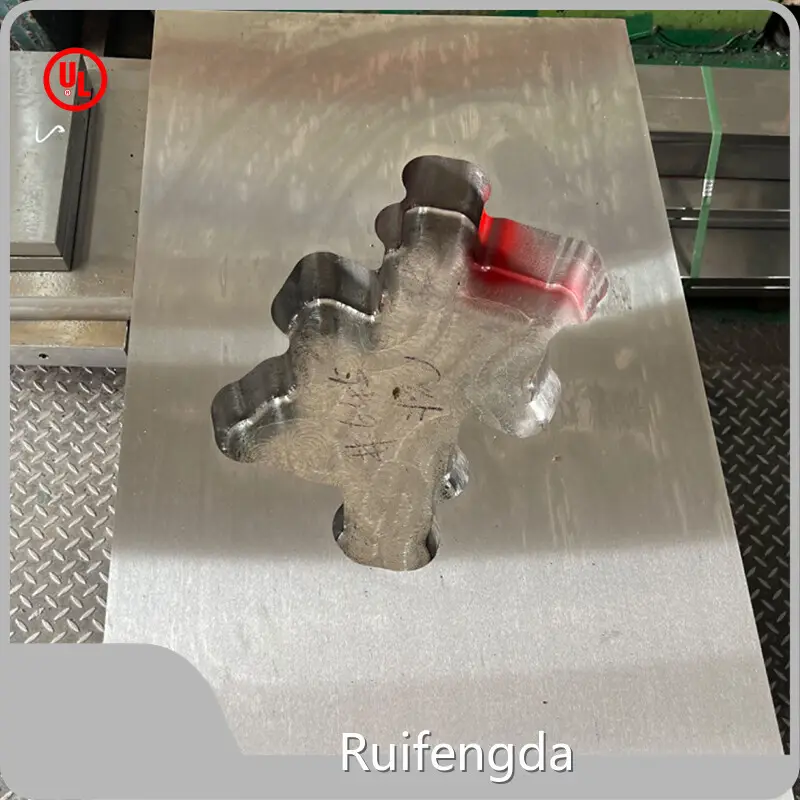

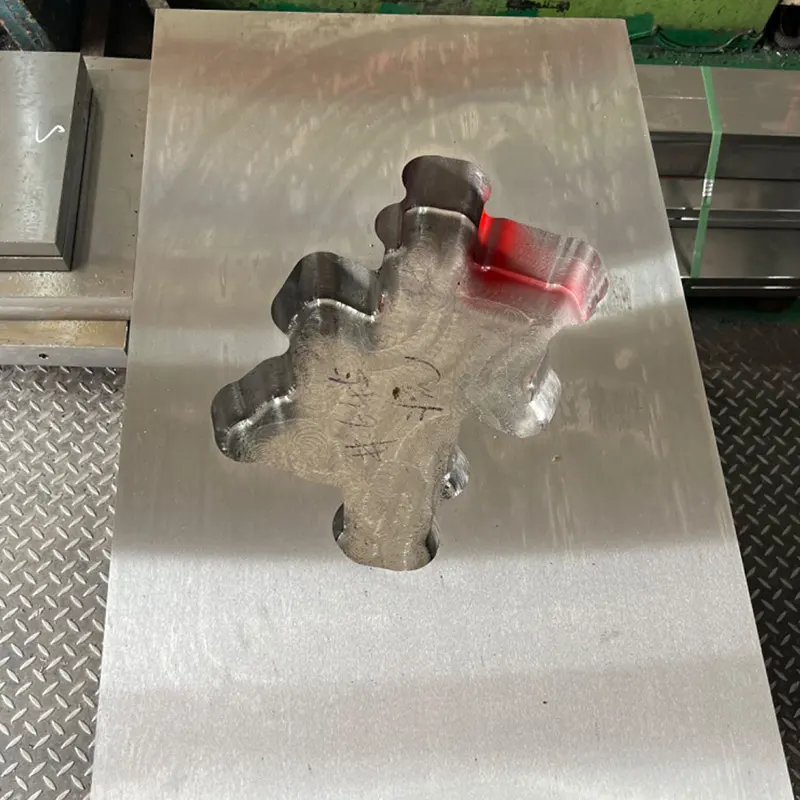

Rough processing

Process the rough shape. After roughening, there needs to be some margin left for subsequent precision machining.

After rough shaping, it is important to leave a margin for subsequent precision machining to ensure that the final product meets the required specifications and tolerances. This margin allows for any necessary adjustments and corrections to be made during the precision machining process, ultimately resulting in a high-quality and accurately dimensioned final product. By allowing for this margin, the rough shaping process sets the stage for the successful completion of the precision machining, ultimately contributing to the overall quality and precision of the final product.

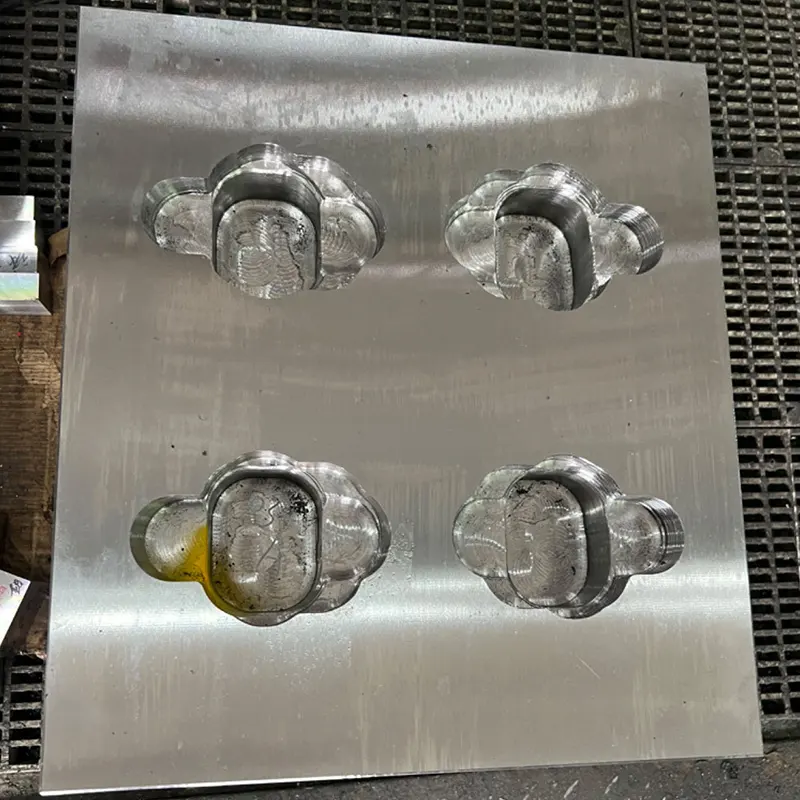

Cavity and core plates

The parallelism and verticality of the pocket must be controlled within 0.02mm. The length, width, and depth tolerance of the precision mould base should be 0~+0.02mm, and the thickness tolerance of the main plates should be ± 0.02mm. Precision machining is essential for screw holes, water line holes, ejector pin holes, nozzle holes, etc. All surfaces must be scratch-free, bright, and flat, and all chamfers must adhere to our company's standards and be uniform. Corresponding precision requirements will be established during the actual machining process based on specific mold design and customer needs.

Runner plate

The aperture and spacing of cavities play crucial roles in the manufacturing process. Precise dimensional tolerance is essential for the aperture to seamlessly fit with mating parts. A smooth surface, free of defects, is necessary to minimize friction and wear, ultimately extending the lifespan of the mold. Consistency in hole spacing within a multi-cavity mold base is vital for ensuring uniformity and stability. Following processing, rigorous CMM testing is carried out to verify the accuracy of the hole spacing.

fAQ

Company Features

· Since its establishment, Ruifengda Brand has been a competitive manufacturer of mold base manufacturers. We have earned a good reputation in the world.

· By introducing high-end technology, Ruifengda has successfully produced qualified mold base manufacturers. High manufacturing depends on our cutting-edge technology. With the introduction of highly advanced technology, Ruifengda not only improves the technical force, but also satisfies the needs of customers.

· Being dedicated to providing mold base manufacturers solutions for users with our best service attitude is something Ruifengda has been always doing. Ask online!

Product Details

Ruifengda's mold base manufacturers is processed based on advanced technology. It has excellent performances in the following details.

Enterprise Advantages

Ruifengda believes that an excellent team is a soul for an enterprise's development. For many years, we have been recruiting talents and elites to build a management team with modern quality and high work efficiency. The team members work together to lead a healthy and efficient development for our company.

Our company has set up a high-quality, experienced and knowledgeable customer service team, which is committed to supplying all-round services to consumers.

Taking 'science and technology innovation' as the driving force of development, Ruifengda Brand provides better products and more satisfactory services for customers, with the help of efficient team, strict quality management system and years of in-depth understanding of the industry.

Our company was established in After years of hard work, we have accumulated a lot of industry experience. Moreover, we are highly recognized by the industry.

Ruifengda's products are sold to many provinces and cities in China. Some are even exported to North America, Eastern Europe, Australia, Southeast Asia, and other regions.