For Industrial Mould Base Plate by Ruifengda

|

Tolerance |

0.02mm-0.005mm |

Rust prevention measures |

Anti rust oil, anti rust spray, vacuum packaging... |

|

Mould life |

300000-500000 Shots |

Transaction mode |

FOB/CIF |

|

Major equipment |

YASDA, OKUMA |

Testing |

CMM, Opening and closing activities... |

|

Size |

Customer Size Accepted |

Supply ability | 300-400 sets per month |

|

Minimum order quantity |

1 Set |

Payment method |

T/T, Paypal, Cash |

|

Material Science |

S50C, P20, 1.2311, 718H, 4Cr13H, 420H, S136H ... |

OEM |

Available |

|

Packing |

Wooden box, plastic film |

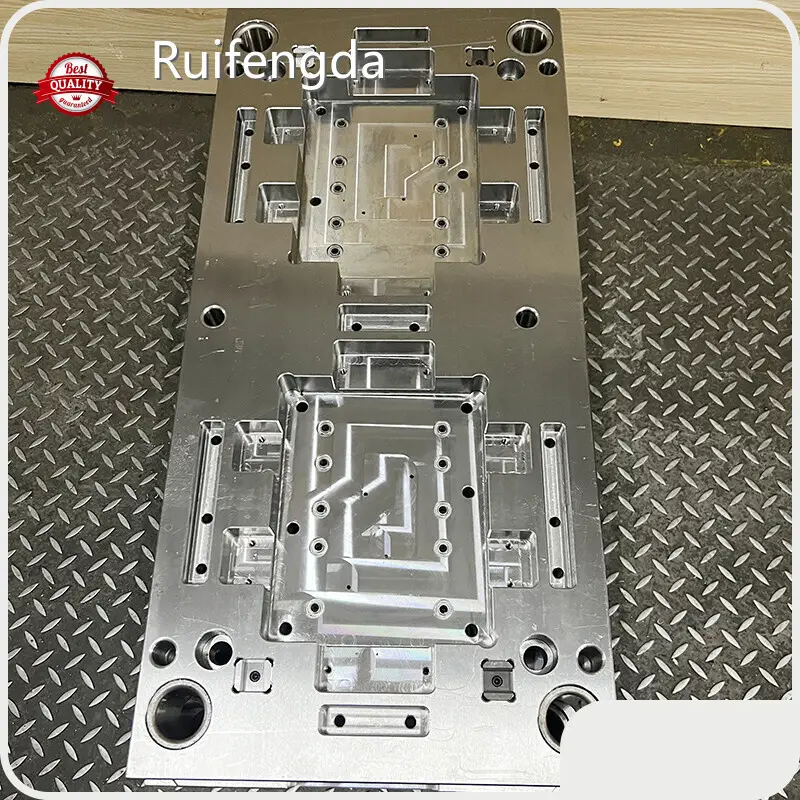

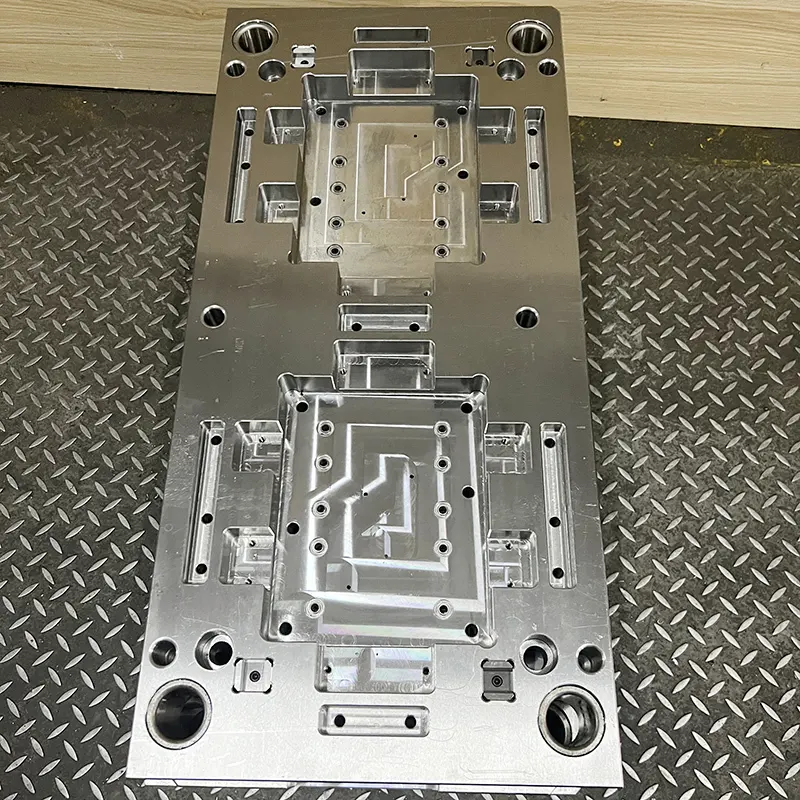

Mold plates

Now there are also some customers who do not order a single complete set of mold base, but only several mold plates. After receiving them, customers process and assemble them by themselves. This method can save a lot of time and shorten product delivery time.

Rough processing

Process the rough shape. After roughening, there needs to be some margin left for subsequent precision machining.

Cavity and core plates

The parallelism and verticality of pocket should be controlled within 0.02mm. The length, width, and depth tolerance of the precision mould base should be 0~+0.02mm, and the thickness tolerance of the main plates should be ± 0.02mm. Precision machining is required for screw holes, water line holes, ejector pin holes, nozzle holes, etc. All surfaces should be scratch free, bright and flat, all chamfers should comply with our company's standards and should be uniform. In the actual machining process, corresponding precision requirements will be formulated based on specific mold design and customer needs.

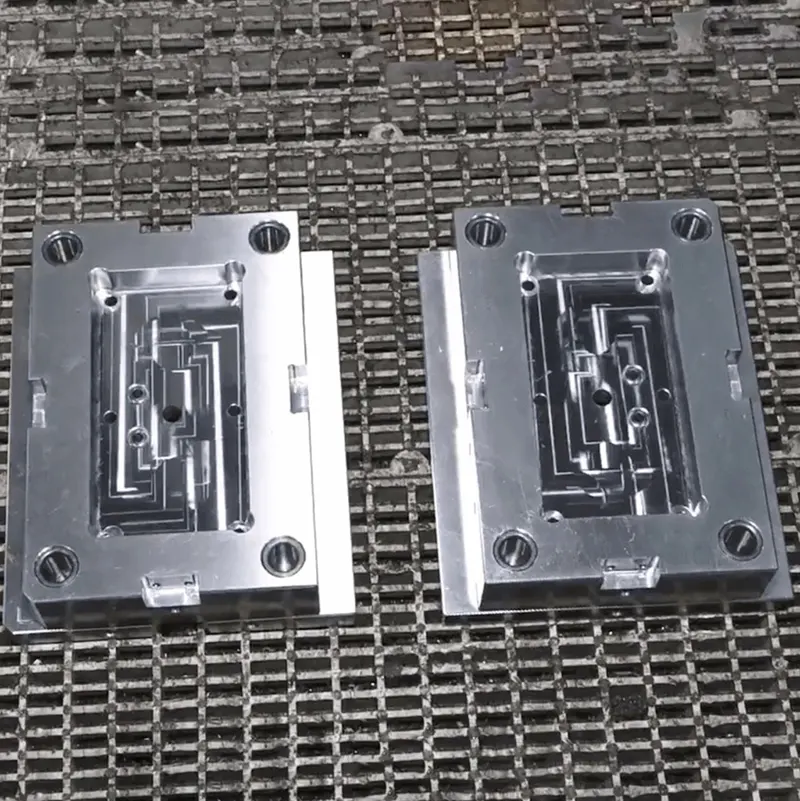

Runner plate

Aperture and spacing of cavities are important parts. The dimensional tolerance of the aperture is within a small range to ensure precise fit with the mating parts. The surface of the aperture is smooth, without scratches, burrs and other defects, which can reduce friction and wear, and improve the life of mold. In a multi cavity mould base, the hole spacing at the same position should be consistent, that is, the hole spacing between each cavity should be equal, which helps to ensure the uniformity and stability of all parts of the mold. After processing, we conduct strict CMM testing on the hole spacing.

fAQ

Company Advantages

· The whole production Ruifengda mould base plate is carried out by highly qualified professionals.

· The product has obtained many international certificates which are the strong testimony of its high quality and performance.

· This Ruifengda branded product will find a ready market overseas.

Company Features

· Ruifengda has gained increasing popularity in the mould base plate market.

· Ruifengda has been operated under the standardized quality management system.

· Based on the concept of 'Quality is the basis for survival,' we seek to grow more steady and stronger step by step. We believe we can be the strongest leader in the mould base plate industry if we attach more importance to quality, including product quality and service quality.

Application of the Product

mould base plate can be applied to different industries, fields and scenes.

Based on customers' specific situations and needs, Ruifengda provides comprehensive and reasonable solutions.