Custom Mold Bases - for Industrial - Ruifengda

Product details of the custom mold bases

Product Description

The source of raw materials: before Ruifengda custom mold bases comes out, it is processed from high quality raw materials. These materials are sourced from several different places within and out of the region. With the careful inspect from our dedicated and skilled crew of quality controllers at every step of production, the performance of this product remains exceptional with zero manufacturing defects. Ruifengda Brand will set a good example for other enterprises in supplying high quality products.

|

Tolerance |

0.02mm-0.005mm |

Rust prevention measures |

Anti rust oil, anti rust spray, vacuum packaging... |

|

Mould life |

300000-500000 Shots |

Transaction mode |

FOB/CIF/EXW |

|

Major equipment |

YASDA, OKUMA |

Testing |

CMM, Opening and closing activities... |

|

Size |

Customer Size Accepted |

Runner |

Hot runner |

|

Minimum order quantity |

1 Set |

Supply ability |

300-400 sets per month |

|

Material Science |

S50C, P20, 1.2311, 718H, 4Cr13H, 420H, S136H ... |

Payment method |

T/T, Paypal, Cash |

|

Packing |

Wooden box, plastic film |

OEM |

Available |

Accessories

All accessories of mould base can be provided according to the drawings. We can provide standard and nonstandard accessories such as HASCO, MISUMI, PUNCH, DME and LKM. Also, we process special accessories including bronze accessories, ball cage bush, self-lubricating parts, etc.

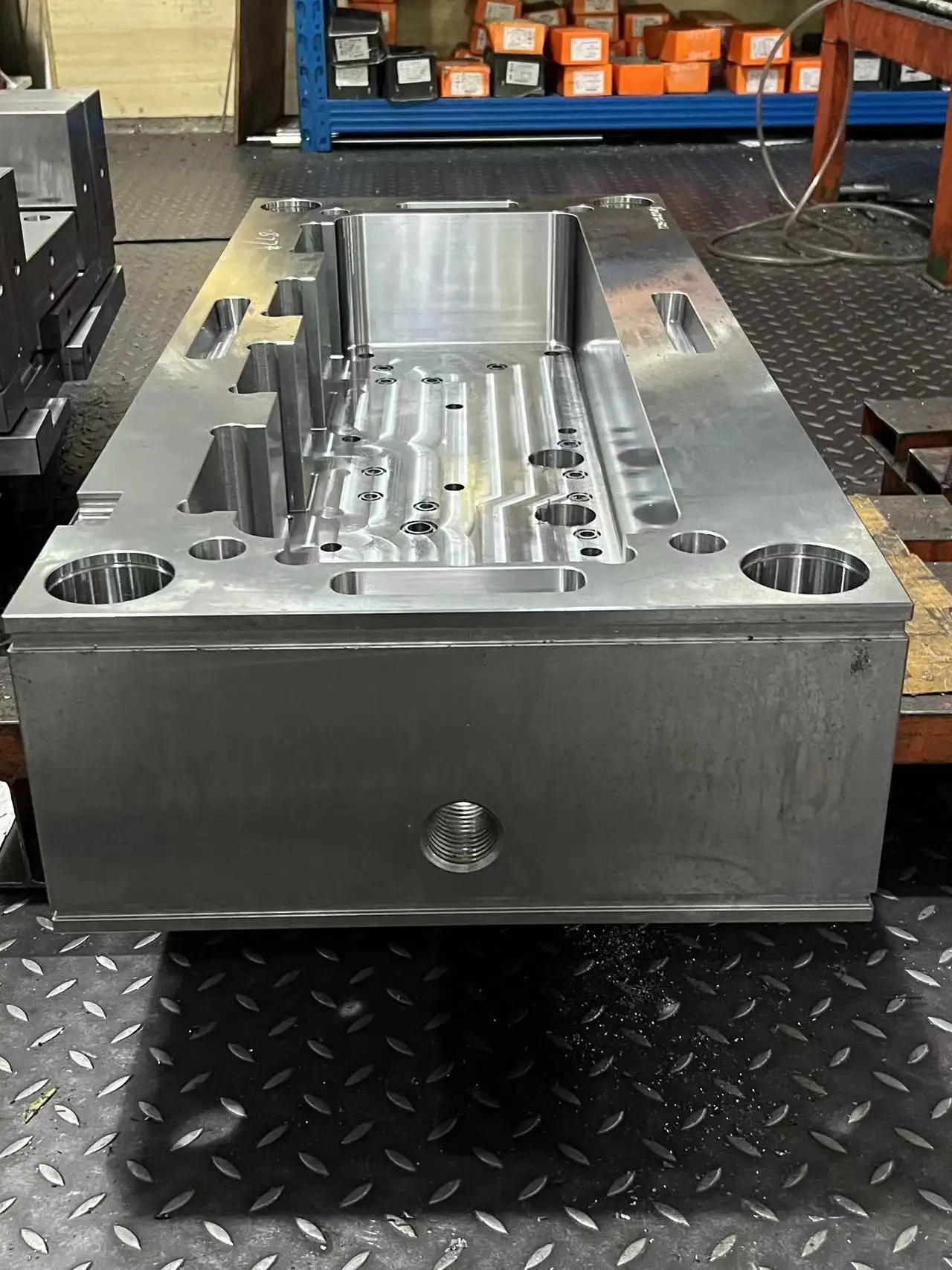

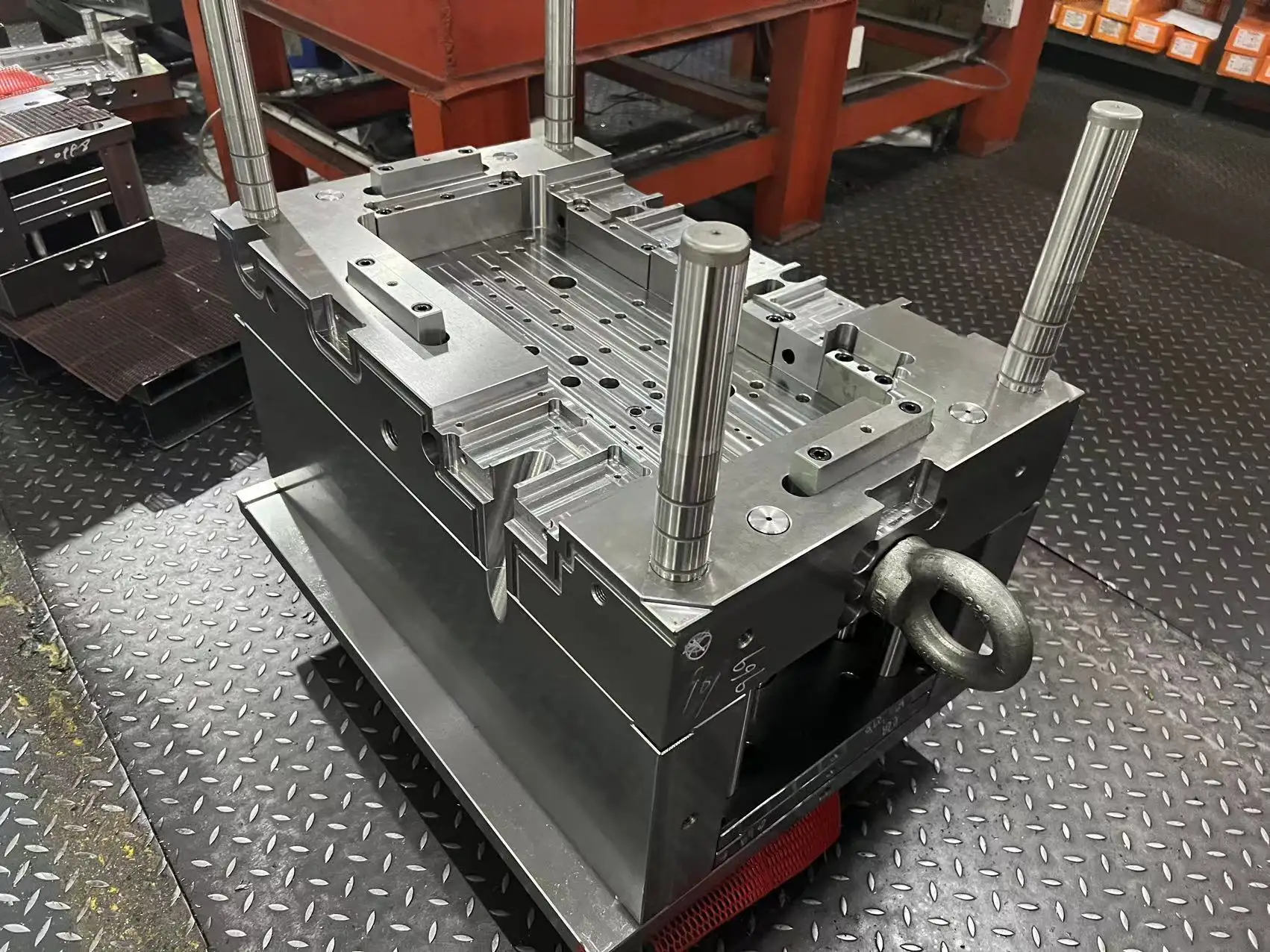

Cavity and core plates

The parallelism and verticality of pocket should be controlled within 0.02mm. The length, width, and depth tolerance of the precision mould base should be 0~+0.02mm, and the thickness tolerance of the main plates should be ± 0.02mm. These are the minimum standard. Precision machining is required for screw holes, water line holes, ejector pin holes, nozzle holes, etc. All surfaces should be scratch free, bright and flat, all chamfers should comply with our company's standards and should be uniform. In the actual machining process, corresponding precision requirements will be formulated based on specific mold design and customer needs.

CNC Machining

We have over ten CNC equipment from brands such as YASDA and OKUMA to meet the high-precision requirements of our customers. Taking YASDA as an example: constant temperature workshop 22 ℃, accuracy 0.003mm, machine travel 900X1500X600mm.

Testing

We use CMM coordinate measurement and generate accurate measurement reports. Its high-precision measurement results can ensure product quality and tolerance requirements.

Anti-corrosion treatment

In order to reduce the impact of rust on mould base during shipping, we will use anti rust spray and anti rust oil on the surface of mould base, and then wrap them with plastic film. If necessary, vacuum packaging will be used.

fAQ

Company Feature

• Formally established in Ruifengda has struggled hard in the industry for many years. Now we are widely recognized depending on advanced technology, quality products, and excellent services.

• Ruifengda introduces a group of experienced and professional talents. They are committed to providing technical support for the production of high-quality products which greatly improves corporate core competency.

• Our company is located in the place with beautiful environment and convenient transportation.

Dear customer, thank you for your attention to this site! If you are not satisfied with our products or have any suggestions, please contact Ruifengda directly. We will serve you wholeheartedly.