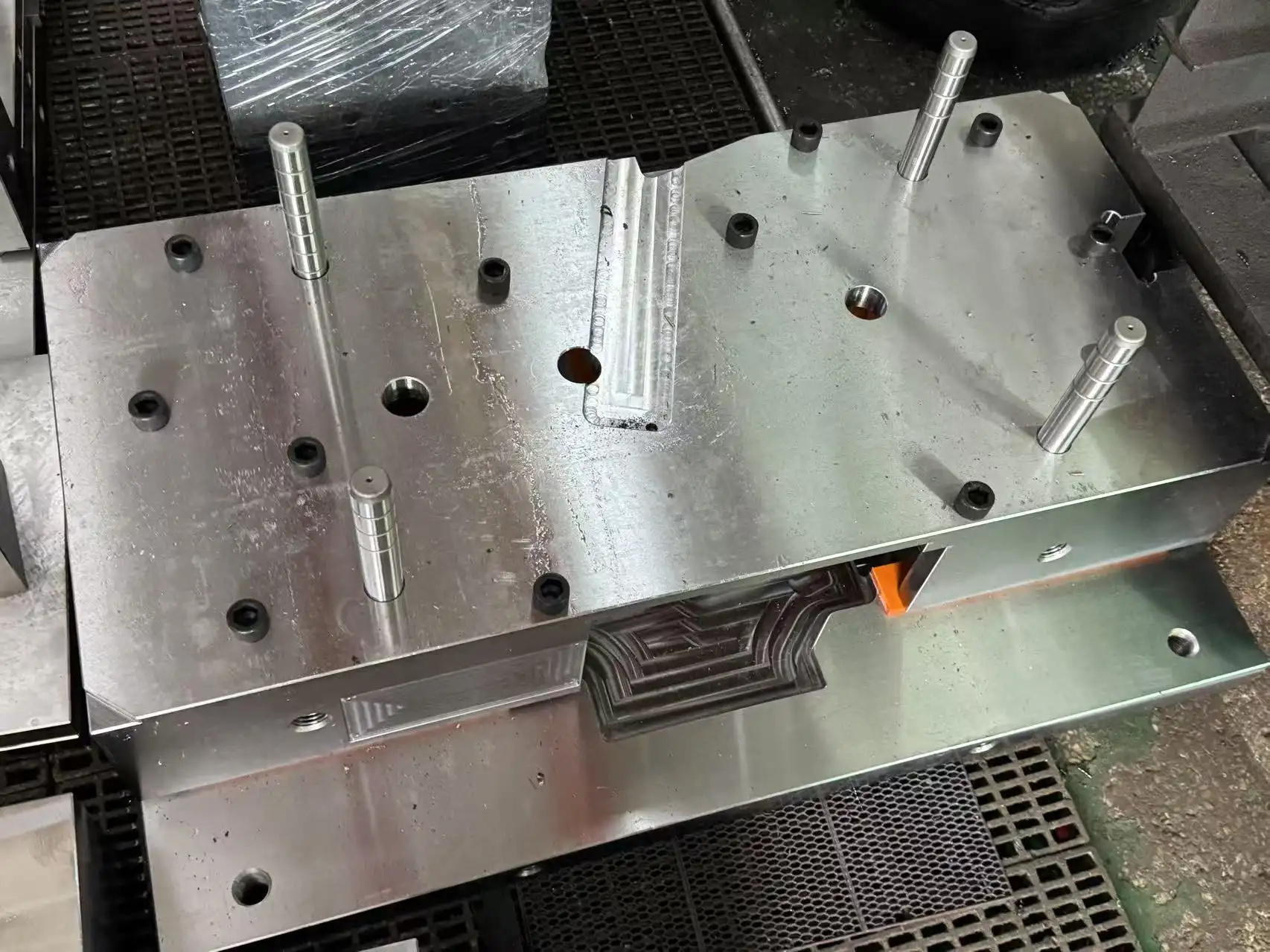

Customized mold base for precision engineering | Supports automotive/medical industries | Free drawing optimization consultation

Custom mold bases are engineered to meet unique project requirements that standard options cannot fulfill. Designed with advanced CAD/CAM technologies, these bespoke solutions accommodate intricate part geometries, specialized cooling systems, and multi-cavity layouts. Ideal for industries like automotive, medical devices, and consumer electronics, our custom mold bases prioritize dimensional accuracy (±0.01mm), material durability (P20, 718H, or S136 steel), and seamless integration with automation systems. Whether you need hybrid structures, asymmetric designs, or non-standard plate thicknesses, we deliver optimized performance while reducing cycle times and minimizing material waste.

Tolerance | 0.02mm-0.005mm | Rust prevention measures | Anti rust oil, anti rust spray, vacuum packaging... |

Mould life | 300000-500000 Shots | Transaction mode | FOB/CIF |

Major equipment | YASDA, OKUMA | Testing | CMM, Opening and closing activities... |

Veľkosť | Customer Size Accepted | Bežec | Horúci bežec |

Minimum order quantity | 1 set | Supply ability | 300-400 sets per month |

Material Science | S50C, P20, 1.2311, 718H, 4Cr13H, 420H, S136H ... | Payment method | T/T, Paypal, Cash |

Balenie | Wooden box, plastic film | OEM | Available |

Customizable Accessories

From HASCO-compatible parts to specialized bronze components, our catalog covers both standard and custom mold base accessories. Whether you need self-lubricating bushings or bespoke ball cage systems, we tailor solutions to your exact requirements

Ultra-Precision Mold Plates

Cavity and core plates are machined to exceptional standards: pocket dimensions controlled within +0.02mm, plate thickness held to ± 0.02mm, and surfaces polished to a mirror finish. All features — including ejector pin holes and cooling channels — are precision-engineered for flawless mold performance

Cutting-Edge CNC Technology

Our facility houses YASDA and OKUMA CNC machines, operating in a 22 ° C constant temperature workshop to minimize thermal expansion. Achieve tolerances as low as 0.003mm, even for large-scale molds up to 1500mm in length

Rigorous Inspection Protocols

Using CMM systems, we validate every dimension and generate comprehensive reports to ensure compliance with your design. This meticulous approach eliminates defects and guarantees repeatable accuracy

Shipping Protection

To combat corrosion during logistics, mold bases are treated with anti-rust coatings and wrapped in moisture-resistant film. Optional vacuum sealing provides extra protection for sensitive components

fAQ

Precision mould base 0.01mm

Ultra-precision mould base 0.005mm