Ultimate Precision: The Advantages Of Machined Mould Bases

Are you in search of the ultimate precision in mould bases for your projects? Look no further! Discover the numerous advantages of machined mould bases in this article. From enhanced accuracy to improved efficiency, find out how machined mould bases can elevate your manufacturing processes. Whether you're a seasoned professional or a newcomer to the industry, this article will provide valuable insights into the benefits of using machined mould bases for your projects.

Understanding Machined Mould Bases

When it comes to creating high-quality and precise plastic parts and components, the importance of using machined mould bases cannot be understated. Machined mould bases are a crucial component in the plastic injection moulding process, and they play a significant role in determining the accuracy, quality, and consistency of the final product. In this article, we will explore the advantages of using machined mould bases and provide a comprehensive understanding of their importance in the manufacturing industry.

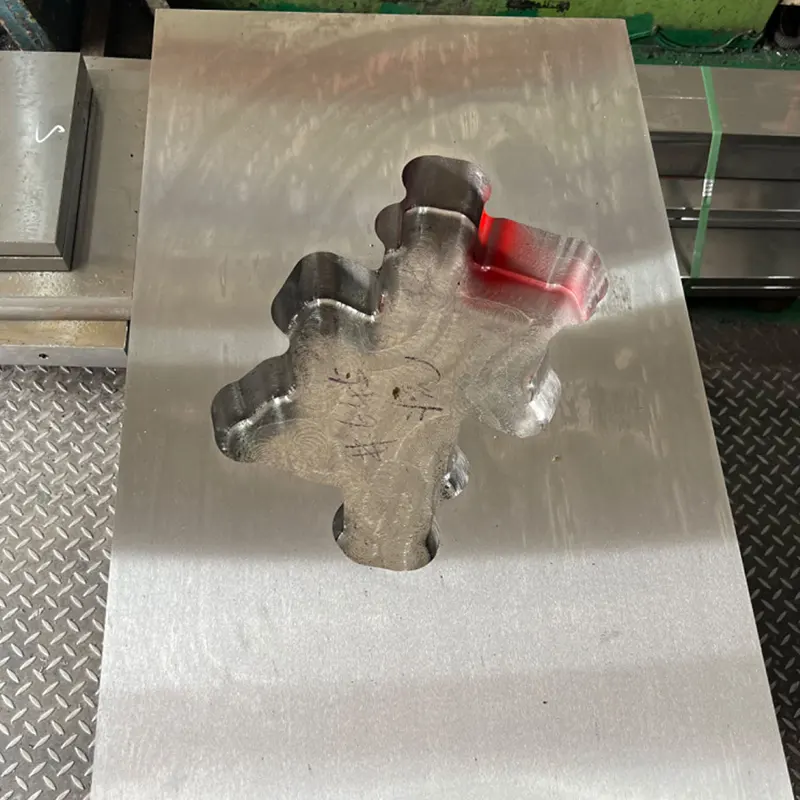

To begin with, it is essential to define what a machined mould base is. A machined mould base is a pre-manufactured steel structure that serves as the foundation for mould making. It is designed to provide a precise and stable platform for the injection moulding process, ensuring that the final product meets the required specifications and tolerances. Machined mould bases are typically made from high-quality steel and are machined with extreme precision to provide a uniform and consistent surface for the moulding process.

One of the primary advantages of using machined mould bases is the level of precision and accuracy that they offer. Machined mould bases are manufactured using advanced CNC machining technology, which allows for incredibly tight tolerances and exacting specifications. This level of precision is critical in the production of complex and intricate plastic parts, as even the smallest deviation can result in defective products. By using machined mould bases, manufacturers can ensure that their products meet the highest standards of quality and consistency.

In addition to precision, machined mould bases also offer enhanced durability and longevity. The use of high-quality steel and advanced machining techniques ensures that machined mould bases are capable of withstanding the rigors of the injection moulding process. This durability not only extends the lifespan of the mould base but also contributes to the overall robustness and reliability of the manufacturing process. This means that manufacturers can rely on machined mould bases to consistently deliver high-quality products without the need for frequent replacements or repairs.

Furthermore, machined mould bases offer flexibility and customization options to meet the specific needs of different manufacturing processes. With the ability to be machined to precise specifications, machined mould bases can accommodate a wide range of mould designs and configurations. This flexibility allows manufacturers to create a diverse range of plastic parts and components without compromising on quality or precision. Whether it's a simple prototype or a complex multi-cavity mould, machined mould bases can be tailored to meet the unique requirements of any project.

In conclusion, a thorough understanding of the advantages of machined mould bases is essential for manufacturers looking to achieve ultimate precision in their injection moulding processes. From the unmatched precision and accuracy to the durability and flexibility they offer, machined mould bases play a critical role in ensuring the quality and consistency of plastic parts and components. By investing in machined mould bases, manufacturers can elevate their manufacturing processes to new levels of excellence and reliability, ultimately leading to improved productivity and customer satisfaction.

The Superior Precision of Machined Mould Bases

Machined mould bases are a critical component in the manufacturing industry, providing the foundation for high-quality and precision-machined parts. The superior precision of machined mould bases offers a range of advantages, making them an essential choice for manufacturers seeking the highest levels of accuracy and reliability in their production processes.

Machined mould bases are produced using advanced machining techniques, which ensure an unparalleled level of precision and consistency. Unlike traditional methods of mould base production, such as casting or forging, machining allows for tight tolerances and exact dimensions. This level of precision is essential in the manufacturing of intricate and complex parts, where even the smallest deviation can result in faulty products.

One of the key advantages of machined mould bases is their ability to meet the exacting requirements of modern manufacturing processes. With industries increasingly demanding higher precision and tighter tolerances, machined mould bases provide the necessary foundation for achieving these standards. The accuracy of machined mould bases ensures that each part produced is of the highest quality, reducing the need for rework and minimizing production waste.

Furthermore, the use of machined mould bases facilitates greater design flexibility. As the mould bases are machined to precise specifications, manufacturers have the freedom to design and produce parts with intricate details and complex geometries. This flexibility opens up new possibilities for product innovation and development, allowing manufacturers to create components that were previously unattainable using traditional mould base production methods.

The superior precision of machined mould bases also contributes to improved efficiency and productivity in the manufacturing process. By ensuring that each part produced is consistently accurate, machined mould bases reduce the need for extensive post-production adjustments and modifications. This results in faster production cycles and reduced lead times, allowing manufacturers to deliver high-quality components to their customers in a timely manner.

In addition to precision, machined mould bases offer enhanced durability and longevity. The use of high-quality materials and the precision machining process results in mould bases that are resistant to wear and deformation. This longevity reduces the frequency of maintenance and replacement, further contributing to the overall efficiency and cost-effectiveness of the manufacturing process.

Overall, the advantages of machined mould bases are clear. Their superior precision, design flexibility, efficiency, and durability make them an essential choice for manufacturers seeking to produce high-quality, reliable, and cost-effective components. As the manufacturing industry continues to demand ever-higher standards of precision and performance, the role of machined mould bases will remain integral to the production of advanced and innovative products.

Advantages of Machined Mould Bases in Manufacturing

Machined mould bases have revolutionized the manufacturing industry, offering a myriad of advantages that have redefined precision and efficiency in the production process. From improved accuracy to enhanced durability, machined mould bases have become an indispensable component in the manufacturing of a wide range of products. In this article, we will explore the numerous advantages of machined mould bases and how they have transformed the manufacturing landscape.

One of the primary advantages of machined mould bases is the unparalleled precision they offer. Through advanced machining techniques, mould bases can be crafted with utmost accuracy, ensuring that the final product meets the exact specifications and tolerances required. This level of precision is crucial in industries such as automotive, aerospace, and medical equipment manufacturing, where even the slightest deviation can result in catastrophic consequences. Machined mould bases provide the level of precision necessary to produce high-quality, flawless products consistently.

In addition to precision, machined mould bases also offer superior durability. The use of high-quality materials and advanced machining processes results in mould bases that are incredibly robust and resistant to wear and tear. This durability not only extends the lifespan of the mould base but also ensures that it can withstand the rigors of high-volume production without compromising on quality. As a result, manufacturers can rely on machined mould bases to deliver consistent performance over an extended period, ultimately reducing downtime and maintenance costs.

Furthermore, machined mould bases provide unmatched versatility in manufacturing. The ability to customize mould bases to specific requirements enables manufacturers to produce a diverse range of products with ease. Whether it's intricate components for electronics or large-scale industrial parts, machined mould bases can be tailored to accommodate various shapes, sizes, and complexities. This flexibility is invaluable in today's dynamic manufacturing environment, allowing companies to adapt to changing market demands and design specifications seamlessly.

Another key advantage of machined mould bases is the efficiency they bring to the manufacturing process. With precise tooling and standardized components, machined mould bases facilitate streamlined production processes, significantly reducing setup times and minimizing waste. This efficiency not only improves overall productivity but also translates to cost savings for manufacturers. By optimizing the manufacturing process with machined mould bases, companies can enhance their competitive edge in the market and realize greater profitability.

Moreover, machined mould bases contribute to improved product consistency and quality. The uniformity and reliability of machined mould bases ensure that each produced component meets the same high standards, minimizing variations and defects. This level of consistency is vital in industries where product performance and safety are paramount, instilling confidence in both manufacturers and end-users.

In conclusion, the advantages of machined mould bases in manufacturing are undeniable. From precision and durability to versatility and efficiency, machined mould bases have set a new standard for excellence in the industry. As technology and machining capabilities continue to advance, the potential for further innovation and improvement in machined mould bases is limitless, promising an even brighter future for manufacturing.

Applications and Industries Benefiting from Machined Mould Bases

Machined mould bases play a crucial role in various industries and applications, providing the ultimate precision and numerous benefits. The process of machining mould bases involves cutting and shaping raw materials to create a base for moulds, which are used in a wide range of manufacturing processes. From automotive to electronics, and from medical to consumer goods, machined mould bases are indispensable in delivering high-quality products and components.

One of the industries benefiting greatly from machined mould bases is the automotive sector. Machined mould bases are used in the production of automotive parts such as engine components, interior and exterior trims, and lighting fixtures. The precision and accuracy of machined mould bases are essential in ensuring the quality and performance of these automotive parts, ultimately contributing to the safety and reliability of vehicles.

The electronics industry also relies heavily on machined mould bases for the production of electronic components and devices. From smartphone casings to circuit boards and connectors, machined mould bases are instrumental in achieving the required level of precision and consistency in the manufacturing process. The demand for smaller, lighter, and more powerful electronic products has necessitated the use of advanced machined mould bases to meet the exacting specifications of the industry.

In the medical field, machined mould bases play a critical role in the production of medical devices, implants, and equipment. The high level of precision and tight tolerances required in the medical industry make machined mould bases an essential component in the manufacturing process. Whether it is producing complex surgical instruments or intricate dental implants, the accuracy and reliability of machined mould bases are paramount in meeting the stringent regulatory standards of the medical sector.

Additionally, the consumer goods industry benefits significantly from the use of machined mould bases in the production of a wide range of products. From household appliances to personal care items, and from toys to packaging components, machined mould bases contribute to the efficiency and consistency of manufacturing processes. The ability to produce intricate and custom-designed moulds allows for the creation of innovative and high-quality consumer goods that meet the diverse needs of the market.

Overall, the advantages of machined mould bases extend across various industries and applications, providing the ultimate precision and reliability required for the production of high-quality products and components. With advancements in technology and materials, machined mould bases continue to play a vital role in driving innovation and meeting the evolving demands of modern manufacturing. As industries continue to push the boundaries of what is possible, machined mould bases will remain an integral part of the manufacturing process, ensuring the production of precise and consistent products.

Choosing Machined Mould Bases for Optimal Results

When it comes to the manufacturing of plastic or metal products, the quality of the mould base plays a crucial role in determining the overall precision and quality of the final products. Machined mould bases have been gaining popularity in the manufacturing industry due to their numerous advantages over other types of mould bases. In this article, we will explore the reasons why choosing machined mould bases can lead to optimal results in the manufacturing process.

Machined mould bases are manufactured using advanced machining techniques, which ensure a high level of precision and accuracy. This means that the dimensions and specifications of the mould base are achieved with utmost accuracy, leading to consistent and reliable performance in the moulding process. As a result, products manufactured using machined mould bases are of superior quality and meet the highest standards of precision.

One of the key advantages of machined mould bases is their durability and longevity. The use of high-quality materials and precision machining processes result in mould bases that are able to withstand the rigors of the manufacturing process. This means that the mould bases are able to maintain their accuracy and reliability over a long period of time, reducing the need for frequent repairs or replacements. This not only leads to cost savings for manufacturers but also ensures a consistent and reliable production process.

In addition, machined mould bases offer a high degree of customization and flexibility. Manufacturers have the ability to specify the exact dimensions, features, and specifications of the mould base to meet the specific requirements of their production process. This level of customization ensures that the mould base is perfectly suited to the needs of the manufacturer, leading to optimal results in the manufacturing process. Whether it’s a complex design or a simple prototype, machined mould bases can be tailored to meet the unique demands of the production process.

Furthermore, machined mould bases are able to provide enhanced performance in terms of cycle times and production efficiency. The precise machining of the mould base leads to smooth and consistent moulding processes, reducing the time required for each cycle. This ultimately leads to increased productivity and cost savings for manufacturers, as the production process becomes more efficient and streamlined.

It is also worth noting that machined mould bases are able to offer improved consistency and repeatability in the production process. The high level of precision and accuracy in the manufacturing of machined mould bases ensures that the final products meet the exact specifications and requirements of the manufacturer. This level of consistency is crucial in industries where even the slightest variation in product dimensions can lead to significant quality issues.

In conclusion, choosing machined mould bases for manufacturing processes can lead to optimal results in terms of precision, durability, customization, performance, and consistency. As the manufacturing industry continues to demand high-quality products with tight tolerances, machined mould bases provide a reliable and efficient solution for achieving the desired outcomes. With their advanced machining techniques and customizable features, machined mould bases are poised to play a crucial role in the future of manufacturing.

Conclusion

In conclusion, machined mould bases offer a range of advantages over other methods of production. With ultimate precision and accuracy, these bases provide a solid foundation for high-quality products and reduced production times. As a company with 18 years of experience in the industry, we understand the importance of using top-notch materials and techniques, and we stand by the benefits of machined mould bases. Whether you are in the automotive, aerospace, medical, or any other industry, investing in machined mould bases can ultimately lead to improved performance and cost savings. So, make the smart choice and consider using machined mould bases for your next manufacturing project.