Maximizing Precision: Exploring The Advantages Of Machined Mould Bases

Are you looking to enhance the precision and efficiency of your manufacturing processes? Look no further - in this article, we delve into the myriad advantages of utilizing machined mould bases to maximize precision in your operations. From improved part consistency to reduced lead times, we explore how this advanced technology can revolutionize your production capabilities. Read on to discover how machined mould bases can elevate your manufacturing processes to new heights.

Understanding the Role of Machined Mould Bases in Precision Manufacturing

Precision manufacturing plays a crucial role in industries such as automotive, aerospace, and medical device manufacturing where the demand for high-quality and accurate parts is paramount. One of the key components in precision manufacturing is the machined mould base, which forms the foundation for creating intricate and precise components. Understanding the role of machined mould bases is essential for maximizing precision in manufacturing processes.

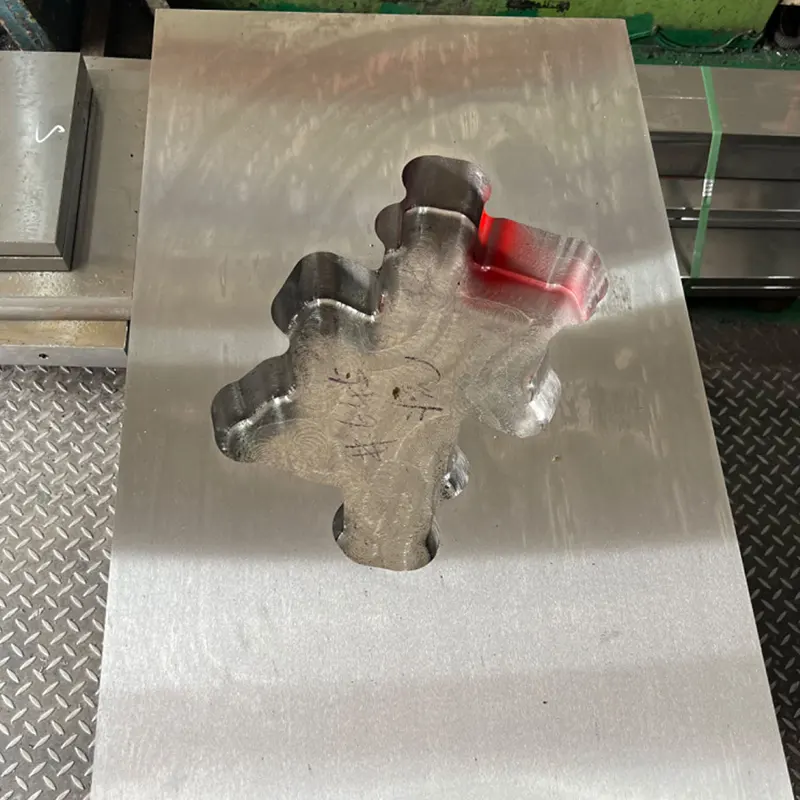

Machined mould bases are the starting point for creating a wide range of components, from simple to highly complex geometries. They serve as the backbone for injection moulding, die casting, and other manufacturing processes, providing the necessary support and stability for producing parts with tight tolerances and exact specifications.

One of the primary advantages of machined mould bases is their ability to provide a solid and stable platform for manufacturing operations. The precision machining of these bases ensures that the resulting components are accurate and consistent, meeting the stringent requirements of the industry. By using machined mould bases, manufacturers can achieve higher levels of precision and repeatability in their production processes, ultimately leading to enhanced product quality and performance.

Furthermore, machined mould bases offer a high degree of customization, allowing manufacturers to tailor the bases to specific production requirements. This flexibility enables the creation of unique mould designs that can accommodate complex part geometries and intricate features. As a result, manufacturers can produce a diverse range of components with varying shapes, sizes, and functionalities, all while maintaining the desired level of precision.

The utilization of machined mould bases also contributes to improved efficiency and cost-effectiveness in manufacturing. The accurate and precise nature of these bases minimizes the need for secondary processes and refining operations, leading to reduced production time and material waste. Additionally, the durability and longevity of machined mould bases result in extended tool life and reduced tooling maintenance, ultimately lowering overall production costs.

In the context of precision manufacturing, the role of machined mould bases cannot be overstated. They form the cornerstone of the production process, providing the necessary support, stability, and precision for creating high-quality components. By understanding the advantages of machined mould bases, manufacturers can optimize their manufacturing processes and achieve superior levels of precision and quality in their products.

In conclusion, the incorporation of machined mould bases in precision manufacturing offers numerous benefits, including enhanced precision, customization, efficiency, and cost-effectiveness. As industries continue to demand increasingly intricate and precise components, the role of machined mould bases becomes even more vital in ensuring the success and competitiveness of manufacturing operations. By recognizing and embracing the advantages of machined mould bases, manufacturers can maximize precision and remain at the forefront of the industry.

The Key Advantages of Using Machined Mould Bases in Production Processes

Machined mould bases play a crucial role in the production processes of various industries. They are an essential component in creating precise and high-quality products, making them a valuable investment for any manufacturing operation. In this article, we will explore the key advantages of using machined mould bases in production processes, and how they contribute to maximizing precision.

One of the most significant advantages of using machined mould bases is their ability to provide unparalleled precision and consistency in the manufacturing process. The use of machined mould bases ensures that the dimensions and specifications of the mould are accurately maintained throughout the production process, resulting in products that meet tight tolerances and exacting standards. This level of precision is essential in industries such as automotive, aerospace, and medical devices, where even the smallest deviation can lead to costly rework or product defects.

Furthermore, machined mould bases are known for their superior durability and longevity. Unlike standard mould bases, which may be susceptible to warping or wear over time, machined mould bases are crafted from high-quality materials such as hardened steel or aluminum. This ensures that they can withstand the rigors of high-volume production and frequent use, without compromising on accuracy or performance. The long-term durability of machined mould bases translates to cost savings for manufacturers, as they eliminate the need for frequent replacement or repairs.

Another key advantage of using machined mould bases is the customization options they offer. Manufacturers can work closely with machined mould base suppliers to create custom designs that meet their specific production requirements. Whether it's intricate geometric shapes, complex contours, or specialized features, machined mould bases can be tailored to accommodate a wide range of design needs. This level of customization allows manufacturers to achieve the exact specifications needed for their products, without any compromises on quality or precision.

In addition to precision, durability, and customization, machined mould bases also offer the advantage of improved heat dissipation. During the injection molding process, heat buildup can negatively impact the quality of the final product. Machined mould bases are engineered to efficiently dissipate heat, preventing any deformities or defects in the moulded parts. This is particularly important in applications where thermal stability is a critical factor, such as in the production of electronic components or precision-engineered parts.

Lastly, the use of machined mould bases can also contribute to overall efficiency in the manufacturing process. With their precise dimensions and high-quality construction, machined mould bases streamline the production process, reducing the need for extensive rework or adjustments. This not only saves time but also increases the overall output of the manufacturing operation. Additionally, the use of machined mould bases can also result in improved product consistency and reduced scrap rates, further enhancing the efficiency and productivity of the production process.

In conclusion, the advantages of using machined mould bases in production processes are clear. From unparalleled precision and durability to customization options and improved heat dissipation, machined mould bases offer a multitude of benefits for manufacturers. By investing in machined mould bases, manufacturers can maximize precision and efficiency in their production processes, ultimately leading to higher-quality products and increased competitiveness in the marketplace.

Strategies for Maximizing Precision through Machined Mould Bases

Precision is a crucial factor in the manufacturing industry, particularly in the field of mould making. The article “Maximizing Precision: Exploring the Advantages of Machined Mould Bases” delves into the strategies for maximizing precision through machined mould bases, shedding light on the numerous advantages they offer.

Machined mould bases play a pivotal role in the manufacturing process, serving as the foundation for creating high-quality moulds. These bases are carefully crafted using advanced machining techniques, ensuring the utmost precision and accuracy. The article emphasizes the importance of employing the right strategies to maximize precision through machined mould bases, thereby elevating the overall quality of the moulds produced.

One of the key strategies highlighted in the article is the use of high-quality materials for machined mould bases. It discusses how the choice of materials directly impacts the precision and durability of the mould base, ultimately influencing the quality of the final mould. By opting for premium materials that are specifically designed for machining, manufacturers can enhance the precision of their mould bases, resulting in superior moulds with impeccable detail and accuracy.

Furthermore, the article delves into the significance of employing advanced machining technology in the production of mould bases. It elucidates how state-of-the-art machining equipment and techniques enable manufacturers to achieve unparalleled precision in their mould bases. From CNC milling to EDM (electrical discharge machining), the article explores the various machining processes that contribute to maximizing precision in machined mould bases.

The article also underscores the importance of strict quality control measures throughout the machining process. It emphasizes the need for meticulous inspection and testing at every stage of production to ensure that the machined mould bases meet the highest standards of precision. By implementing rigorous quality control protocols, manufacturers can safeguard the integrity of their mould bases and uphold the utmost levels of precision.

Additionally, the article delves into the relevance of design optimization in maximizing precision through machined mould bases. It stresses the significance of leveraging innovative design techniques to enhance the functionality and precision of the mould bases. By integrating features such as precision-machined pockets and mounting surfaces, manufacturers can elevate the overall performance and accuracy of their mould bases.

The article concludes by emphasizing the manifold advantages of employing machined mould bases in the manufacturing industry. It underscores how these precision-crafted bases serve as the cornerstone for creating high-quality moulds with intricate detail and flawless precision. By adopting the strategies outlined in the article, manufacturers can harness the full potential of machined mould bases and elevate the quality of their mould production.

In conclusion, the article “Maximizing Precision: Exploring the Advantages of Machined Mould Bases” provides valuable insights into the strategies for maximizing precision through machined mould bases. By focusing on the use of high-quality materials, advanced machining technology, stringent quality control measures, and design optimization, manufacturers can harness the full potential of machined mould bases and elevate the precision and quality of their moulds.

Exploring the Versatility of Machined Mould Bases in Various Industries

Machined mould bases are crucial components in various industries that rely on precision manufacturing. From automotive to aerospace, from medical to consumer goods, the versatility of machined mould bases is evident in the wide range of applications they support. In this article, we will explore the advantages of machined mould bases and how they are utilized in different industries to maximize precision and efficiency.

One of the key advantages of machined mould bases is their precision and consistency. These bases are manufactured using advanced machining techniques, such as CNC milling and turning, which ensure tight tolerances and accurate dimensions. This level of precision is essential in industries where even the smallest deviation can have a significant impact on the quality and performance of the final product.

In the automotive industry, machined mould bases are used in the production of a wide range of components, from engine parts to interior trim pieces. The precision of machined mould bases is essential in ensuring the structural integrity and dimensional accuracy of these components. Whether it's the precise molding of complex engine components or the production of intricate interior trim pieces, machined mould bases play a critical role in delivering high-quality automotive products.

In the aerospace industry, where safety and reliability are paramount, machined mould bases are utilized in the production of complex and high-performance components. These mould bases are used to create intricate aerospace components, such as turbine blades and structural components, where precision and material integrity are of the utmost importance. The versatility of machined mould bases allows for the production of a wide range of aerospace components, from small intricate parts to large structural components.

In the medical industry, machined mould bases are essential in the production of medical devices and equipment. These bases are used to create precise and intricate components, such as surgical instruments, implants, and diagnostic equipment. The reliability and precision of machined mould bases ensure that medical devices meet strict regulatory standards and perform with the utmost accuracy and consistency.

In the consumer goods industry, machined mould bases are utilized in the production of a wide range of products, from electronics to household appliances. The precision and versatility of these bases allow for the production of complex and aesthetically pleasing components, such as smartphone casings and home appliance parts. Machined mould bases ensure that consumer goods meet the demands of modern consumers for high-quality, reliable products.

In conclusion, the versatility of machined mould bases in various industries is a testament to their precision, consistency, and reliability. From automotive to aerospace, from medical to consumer goods, machined mould bases play a critical role in delivering high-quality products. Their ability to support a wide range of applications makes them indispensable components in modern manufacturing. As industries continue to push the boundaries of innovation and precision, machined mould bases will remain essential in maximizing precision and efficiency.

Leveraging Machined Mould Bases for Improved Efficiency and Cost Savings

When it comes to the manufacturing of molds and tooling, the use of machined mould bases has become increasingly popular in recent years. The process of leveraging machined mould bases has shown significant advantages in terms of improved efficiency and cost savings for manufacturers. In this article, we will explore the various benefits of utilizing machined mould bases and how they can maximize precision in the manufacturing process.

Machined mould bases are an essential component in the production of precision molds and tooling. Unlike traditional mould bases that are fabricated through casting or forging, machined mould bases are produced using advanced machining techniques. This allows for a higher degree of precision and consistency in the final product, resulting in improved quality and performance.

One of the key advantages of utilizing machined mould bases is the level of customization and flexibility they offer. With traditional mould bases, manufacturers are often limited to standard sizes and configurations, which can be restrictive in certain applications. Machined mould bases, on the other hand, can be tailored to meet the specific requirements of a project, allowing for greater flexibility and adaptability in the manufacturing process.

In addition to customization, machined mould bases also provide improved efficiency in the production of molds and tooling. The precision and consistency achieved through machining result in reduced lead times and improved overall productivity. This is particularly beneficial for manufacturers working on tight deadlines or high-volume production runs, where efficiency is paramount.

Furthermore, the use of machined mould bases can lead to significant cost savings for manufacturers. While the initial investment in machined mould bases may be higher than that of traditional mould bases, the long-term benefits outweigh the upfront costs. The improved efficiency and precision achieved through machined mould bases can reduce scrap rates and rework, ultimately saving manufacturers time and money in the production process.

Another advantage of leveraging machined mould bases is the enhanced quality and performance of the final molds and tooling. The precise dimensions and consistency achieved through machining result in molds that produce more accurate and reliable parts. This is critical in industries such as automotive, aerospace, and medical, where precision and quality are of the utmost importance.

In conclusion, the use of machined mould bases offers significant advantages for manufacturers looking to maximize precision and efficiency in the production of molds and tooling. The customization, flexibility, efficiency, cost savings, and improved quality achieved through machined mould bases make them a valuable investment for manufacturers across a range of industries. As technology continues to advance, it is likely that we will see an increasing reliance on machined mould bases as a standard in the manufacturing process.

Conclusion

In conclusion, the advantages of machined mould bases cannot be understated. With precise accuracy and high-quality materials, these bases offer a range of benefits for companies in various industries. With 18 years of experience in the industry, we understand the importance of maximizing precision in all aspects of production. Machined mould bases have proven to be a valuable investment for our company, allowing us to achieve superior results and meet the demands of our clients. As technology continues to advance, we look forward to exploring new opportunities and techniques for further enhancing our manufacturing processes and delivering exceptional products to our customers.