Precision And Perfection: The Beauty Of Machined Plates

Discover the artistry and precision of machined plates in our latest article, "Precision and Perfection: The Beauty of Machined Plates." Dive into the world of intricate craftsmanship and elegant design as we explore the beauty and functionality of these meticulously crafted pieces. Whether you're a connoisseur of fine engineering or simply appreciate the allure of precision work, this article is sure to pique your interest and leave you with a newfound appreciation for the art of machining.

Understanding the Art of Machined Plates

Machined plates are a fundamental element in the process of precision engineering, and they represent the intersection of art and science in the manufacturing world. Understanding the art of machined plates involves delving into the intricate processes and meticulous craftsmanship behind their production, as well as appreciating the beauty and functionality that they bring to a wide range of industries.

Machined plates are generally made from metal or plastic materials and are crafted with extreme precision through processes such as milling, turning, and grinding. The result is a flat surface with highly accurate dimensions and finishes, making them essential components in industries such as aerospace, automotive, medical, and electronics.

The art of machined plates begins with the selection of materials that are best suited for the intended application. For example, aluminum and steel are commonly used for their strength and durability, while plastics such as PVC and acrylic are favored for their versatility and corrosion resistance. Each material requires a specific set of machining techniques to achieve the desired results, and skilled machinists are essential in translating design specifications into tangible, high-quality plates.

Precision is the hallmark of machined plates, and this precision is achieved through advanced machining technologies and tools. Computer Numerical Control (CNC) machines, for example, use computer-aided design (CAD) software to program the precise movements of cutting tools, resulting in extremely accurate and consistent parts. Additionally, the use of advanced measuring instruments such as coordinate measuring machines (CMM) ensures that machined plates meet strict tolerances and specifications.

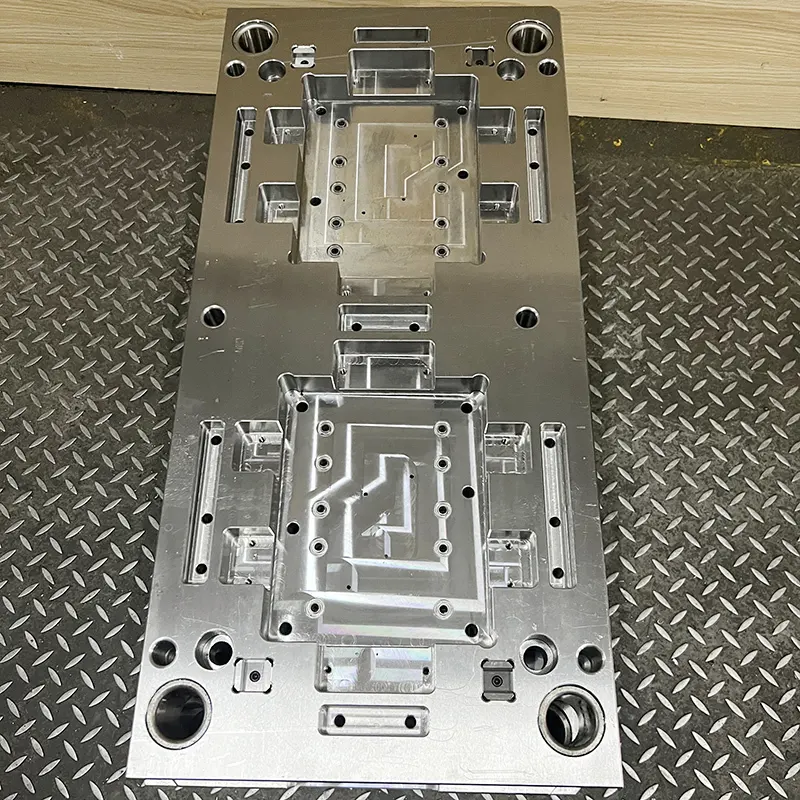

The beauty of machined plates lies in their immaculate surfaces, sharp edges, and fine details. Whether it's a custom instrument panel for a medical device or a precision fixture for a manufacturing process, machined plates exemplify the marriage of form and function. The visual appeal of a well-crafted machined plate is a testament to the skill and expertise of the machinist, as well as the state-of-the-art manufacturing technologies employed in its creation.

Moreover, the functionality of machined plates extends beyond their aesthetics. These components serve as critical building blocks for various machinery and equipment, providing the necessary support, precision, and stability required for the seamless operation of complex systems. From mounting surfaces for sensors and actuators to base plates for industrial machinery, machined plates play an indispensable role in enabling technological advancements across multiple industries.

In essence, understanding the art of machined plates entails recognizing the meticulous craftsmanship, advanced technologies, and functional elegance that define their production and purpose. As the demand for precision engineering continues to grow, the significance of machined plates as essential components in modern manufacturing cannot be overstated. Embracing the art of machined plates means acknowledging the pivotal role they play in shaping the world of engineering and design, from both an aesthetic and functional standpoint.

The Unparalleled Precision of Machined Plates

The Beauty of Machined Plates: The Unparalleled Precision

Machined plates are a marvel of engineering and precision. These plates are created using advanced machining techniques that allow for unparalleled accuracy and uniformity. Whether used in industrial machinery, aerospace components, or medical devices, machined plates are essential for ensuring the highest levels of performance and reliability.

The process of machining plates begins with carefully selected materials, such as aluminum, steel, or titanium. These materials are then shaped and refined using cutting-edge CNC machines, which are capable of incredibly precise movements and measurements. The result is a perfectly flat and smooth surface, with tolerances that can be measured in microns.

One of the key advantages of machined plates is their exceptional dimensional stability. Unlike cast or molded components, machined plates retain their shape and accuracy over time, making them ideal for applications where consistency is critical. This stability is particularly important in high-precision machinery, where even the slightest deviation can lead to performance issues or premature wear.

In addition to their precision, machined plates are also prized for their strength and durability. The rigidity of machined plates allows them to withstand heavy loads and harsh environments without warping or deforming. This makes them an excellent choice for applications where reliability and longevity are paramount.

Furthermore, machined plates can be customized to suit the unique requirements of a particular application. Features such as holes, threads, and complex geometries are easily incorporated into the design, thanks to the flexibility of CNC machining. This allows for the creation of highly specialized components that meet the exacting standards of modern industry.

The beauty of machined plates lies not only in their technical excellence, but also in their aesthetic appeal. The pristine, uniform surfaces of machined plates exude a sense of precision and quality that is unmistakable. This visual perfection reflects the meticulous care and attention to detail that goes into their production, and serves as a testament to the capabilities of modern manufacturing technology.

In conclusion, machined plates are a testament to the marriage of precision and perfection. Their unparalleled accuracy, dimensional stability, strength, and customizable nature make them a cornerstone of modern engineering. Whether used in aerospace, automotive, or medical applications, machined plates are an indispensable component that enables the creation of cutting-edge and reliable machinery. The beauty of machined plates lies in their flawless execution, and the impact they have on the performance and reliability of the products in which they are incorporated.

Craftsmanship and Attention to Detail

Craftsmanship and attention to detail are the hallmark of machined plates, representing the precision and perfection that goes into their creation. These plates are a testament to the dedication and expertise of the artisans who craft them, as well as the beauty and functionality they bring to various industries.

Machined plates are used in a variety of applications, including aerospace, automotive, industrial, and medical fields. They are made from a range of materials, such as aluminum, steel, titanium, and composite materials, and are integral components in machinery, equipment, and structures. The process of machining plates involves the use of precision cutting tools and techniques to shape, cut, and form the material into the desired dimensions and specifications.

Craftsmanship plays a crucial role in the creation of machined plates. Skilled machinists and engineers work collaboratively to design and develop the plates, ensuring that they meet the required standards and tolerances. Each plate is meticulously crafted, with a keen eye for detail and a commitment to excellence. The craftsmanship involved in machining plates requires the highest level of skill, expertise, and attention to detail, resulting in products of exceptional quality and precision.

Attention to detail is another key aspect of machining plates. Every step of the manufacturing process is carefully monitored and executed with precision. From the selection of materials and tooling to the programming of CNC machines and the inspection of finished parts, meticulous attention to detail is paramount. This level of care and precision ensures that the machined plates meet the exact specifications and requirements of their intended use.

The beauty of machined plates lies in their flawless finish and precise dimensions. The smooth, polished surfaces and intricate shapes of machined plates are a testament to the skill and dedication of the craftsmen who create them. These plates not only showcase the technical prowess of the manufacturers but also serve as functional and aesthetic components in the products and equipment they are utilized in.

Moreover, the durability and reliability of machined plates are a result of the attention to detail and precision in their creation. These plates are designed to withstand the rigors of their intended applications, whether it be in high-stress environments, extreme temperatures, or corrosive conditions. The precision engineering and craftsmanship that goes into machining plates ensure that they perform optimally, providing long-lasting and dependable service.

In conclusion, the beauty of machined plates lies in the craftsmanship and attention to detail that goes into their creation. These plates are a testament to the precision and perfection of their manufacturing process, and serve as vital components in a wide range of industries. The skill, expertise, and dedication of the artisans who craft machined plates are reflected in the exceptional quality, durability, and functionality of these products.

The Beauty of Flawless Finished Products

When it comes to the manufacturing and engineering industries, precision and perfection are key to producing high-quality products. One particular area where this is especially important is in the production of machined plates. Machined plates are essential components in a wide range of industrial applications, and their flawless finished products are not only visually appealing but also crucial for ensuring the efficient and reliable operation of machinery and equipment.

Machined plates are commonly used in the manufacturing of tools, fixtures, molds, and various other industrial components. These plates are typically made from metals such as steel, aluminum, or titanium, and are subjected to a machining process that involves cutting, drilling, milling, and other machining operations to achieve the desired specifications and dimensions.

The beauty of flawless finished machined plates lies in the meticulous attention to detail and precision that goes into their production. Machining processes such as CNC milling and turning enable manufacturers to achieve incredibly tight tolerances and smooth surface finishes, resulting in machined plates that are not only aesthetically pleasing but also highly functional.

One of the most striking aspects of flawless finished machined plates is their impeccable surface quality. Through precise machining operations, manufacturers are able to produce plates with smooth, uniform surfaces that are free from imperfections such as scratches, dents, or rough edges. This level of surface quality is not only visually appealing but also critical for ensuring the proper functioning of the machined plates within the intended application.

In addition to surface quality, the dimensional accuracy of machined plates is another defining characteristic of their flawless finished products. Machining processes such as CNC milling and turning allow manufacturers to achieve incredibly tight tolerances and exacting dimensions, ensuring that the machined plates meet the precise specifications required for their intended use. This level of dimensional accuracy is essential for ensuring the proper fit and function of the machined plates within the larger assembly or system.

Furthermore, the overall aesthetic appeal of flawless finished machined plates should not be overlooked. The clean, precise, and uniform appearance of these plates is a testament to the craftsmanship and expertise that goes into their production. The smooth surfaces, sharp edges, and exacting dimensions of machined plates reflect the dedication to quality and precision that is characteristic of the manufacturing and engineering industries.

Overall, the beauty of flawless finished machined plates is a testament to the precision and perfection that are inherent in their production. From impeccable surface quality to exacting dimensional accuracy, these plates are a shining example of the high standards and meticulous attention to detail that define the manufacturing and engineering industries. Whether they are used in aerospace, automotive, medical, or other industrial applications, machined plates with flawless finished products are a testament to the art and science of precision manufacturing.

Applications and Benefits of Machined Plates in Various Industries

Machined plates are an essential component in various industries, and their applications and benefits are truly remarkable. These precision-crafted plates play a crucial role in ensuring the smooth functioning of a wide range of machinery and equipment, making them indispensable in numerous sectors such as aerospace, automotive, manufacturing, and medical.

In the aerospace industry, machined plates are used in the fabrication and assembly of aircraft components. These plates are manufactured with intricate detail and precision to meet the stringent requirements of the aerospace sector. From structural components to engine parts, machined plates are utilized in numerous applications, where their durability and strength are paramount. The high degree of accuracy and fine finishing of machined plates ensures that they can withstand the extreme conditions encountered in aerospace operations, making them a crucial part of the industry's success.

In the automotive industry, machined plates are utilized in the production of engine components, transmission systems, and suspension parts. The precision machining of these plates ensures that each component meets the exact specifications required for optimal performance. The use of machined plates in the automotive sector also contributes to improved fuel efficiency, reduced emissions, and enhanced vehicle safety. With the increasing demand for electric and hybrid vehicles, machined plates are playing a vital role in the development of advanced technology for the automotive industry.

The manufacturing industry relies heavily on the use of machined plates for the production of various equipment and machinery. These plates are used in the manufacturing of precision tools, molds, and dies, where their accuracy and consistency are crucial for achieving high-quality and consistent output. Machined plates are also utilized in the fabrication of industrial machinery, where their durability and resistance to wear and tear are essential for prolonged operational use. The application of machined plates in the manufacturing sector contributes to the overall efficiency and reliability of production processes, leading to improved productivity and cost-effectiveness.

In the medical industry, machined plates are used in the production of medical devices, surgical instruments, and diagnostic equipment. The high level of precision and quality control in the manufacturing of these plates is critical to ensuring the safety and effectiveness of medical products. Machined plates are also utilized in the production of prosthetics and implants, where their biocompatibility and precision are essential for successful patient outcomes. The application of machined plates in the medical sector is integral to the advancement of healthcare technology, leading to improved treatment options and better patient care.

In conclusion, the applications and benefits of machined plates in various industries are vast and significant. Their precision craftsmanship and durability make them indispensable components in aerospace, automotive, manufacturing, and medical sectors. The use of machined plates contributes to the overall advancement of technology and innovation in these industries, leading to improved efficiency, reliability, and safety. As the demand for high-quality and high-performance products continues to grow, the importance of machined plates in various industries will only continue to increase.

Conclusion

In conclusion, the precision and perfection of machined plates truly showcase the beauty of engineering and craftsmanship. As a company with 18 years of experience in the industry, we understand the importance of delivering high-quality machined plates that meet the exact specifications and requirements of our clients. Whether it's for industrial, automotive, or aerospace applications, our dedication to precision and perfection sets us apart. We are committed to continuing to provide top-notch products and services, and we look forward to serving our customers for many more years to come. Thank you for joining us on this journey of appreciating the beauty of machined plates.