Exploring The Versatility Of Machined Plates: From Manufacturing To End-Use Applications

Welcome to our in-depth exploration of machined plates and their wide-ranging versatility. In this article, we will delve into the various manufacturing processes involved in producing machined plates and uncover the multitude of end-use applications for these highly adaptable components. Whether you are a seasoned industry professional or a curious onlooker, join us as we unravel the complexities and possibilities of machined plates in the modern world.

- Introduction to Machined Plates: Understanding Their Role in Manufacturing and End-Use

to Machined Plates: Understanding Their Role in Manufacturing and End-Use

Machined plates are an essential component in various manufacturing and end-use applications. They play a crucial role in providing support, stability, and precision in a wide range of industries, from aerospace and automotive to construction and electronics. Understanding the versatility and significance of machined plates is key to optimizing their potential in manufacturing and end-use applications.

At the core of machined plates is their ability to provide a solid and reliable foundation for machinery, equipment, and structures. These plates are typically made from a range of materials, including metals such as aluminum, steel, and titanium, as well as plastics and composite materials. The choice of material depends on the specific requirements of the application, including strength, weight, and corrosion resistance.

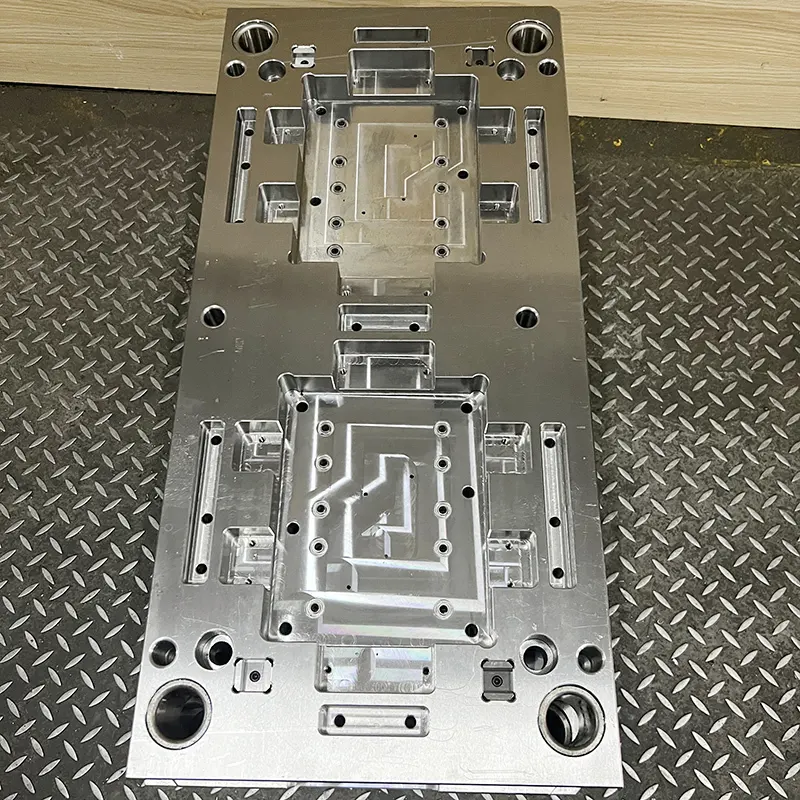

In manufacturing, machined plates are used in various processes, such as milling, turning, drilling, and grinding, to achieve precise dimensions and surface finishes. These plates are essential for creating components and parts with tight tolerances and complex geometries. Additionally, machined plates are often used as fixtures and jigs to hold workpieces in place during machining operations, ensuring accuracy and repeatability.

One of the key advantages of machined plates is their ability to withstand heavy loads and forces, making them ideal for use in structural and mechanical applications. In industries such as automotive and aerospace, machined plates are used in the construction of chassis, frames, and engine components, where strength and durability are critical. Similarly, in the construction industry, machined plates are used in the assembly of heavy machinery, cranes, and structural frames.

In addition to their role in manufacturing, machined plates also have a significant impact on end-use applications. For example, in the electronics industry, machined plates are used as heat sinks to dissipate thermal energy from electronic components, ensuring reliable operation and longevity. In the medical field, machined plates are utilized in the production of prosthetics, implants, and surgical instruments, where precision and biocompatibility are essential.

Furthermore, machined plates are increasingly being used in the realm of renewable energy, particularly in the construction of wind turbines and solar panels. The ability of machined plates to provide stability and support in challenging environments makes them ideal for these applications, where exposure to high winds, temperature variations, and corrosive elements is common.

Overall, the versatility of machined plates extends across a wide range of industries and applications, where their role in providing stability, precision, and durability is paramount. As technology continues to advance, the demand for machined plates with increasingly complex geometries and material properties is expected to grow, further emphasizing their importance in manufacturing and end-use applications. Understanding the different types of machined plates and their specific capabilities is essential for optimizing their performance and ensuring the success of various industrial processes and end-use applications.

- The Manufacturing Process: Exploring the Techniques and Technologies Used in Machining Plates

Machined plates are a critical component in a wide range of industries, from aerospace and automotive to manufacturing and construction. The manufacturing process of machining plates involves a series of intricate techniques and cutting-edge technologies that ensure the end product meets the rigorous demands of its intended application. In this article, we will explore the various techniques and technologies used in machining plates, as well as their end-use applications.

Machining plates involves the process of removing material from a workpiece to create a desired shape, size, and surface finish. The process begins with the selection of a suitable material, such as steel, aluminum, or titanium, which is then secured onto a precision machining center. The machining process itself can be carried out using a variety of techniques, including milling, turning, drilling, and grinding, each of which serves a specific purpose in shaping the workpiece.

Milling is one of the most commonly used techniques in machining plates, involving the use of a rotating cutting tool to remove material from the workpiece. This process is highly versatile and can be used to create a wide range of shapes and features, from simple holes and slots to complex contours and profiles. Turning, on the other hand, is used to create cylindrical components by rotating the workpiece against a stationary cutting tool. This technique is particularly well-suited for producing round or cylindrical parts, such as shafts, pins, and bushings.

Drilling is used to create precise holes in the workpiece, while grinding is employed to achieve a high level of surface finish and dimensional accuracy. These techniques, when used in combination, allow manufacturers to create machined plates with the exact specifications required for their end-use applications.

In addition to traditional machining techniques, the manufacturing process of machining plates also incorporates advanced technologies such as computer numerical control (CNC) machining, which allows for precise and repeatable production of complex parts. CNC machining involves the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software to control the movement of the machining tools, resulting in highly accurate and efficient production of machined plates.

The end-use applications of machined plates are vast and diverse, ranging from structural components in the aerospace industry to tooling and fixturing in manufacturing. In aerospace, machined plates are used to create critical components such as wing spars, bulkheads, and landing gear, which require high strength-to-weight ratios and precise dimensional accuracy. In the automotive industry, machined plates are utilized in the production of engine components, transmission parts, and suspension systems, where durability and reliability are paramount.

In conclusion, the manufacturing process of machining plates involves a combination of intricate techniques and cutting-edge technologies that culminate in the production of high-quality, precise, and versatile components. Whether utilized in aerospace, automotive, manufacturing, or construction, machined plates play a crucial role in the advancement of modern technology and industry.

- Versatile Applications: How Machined Plates are Utilized in Various Industries

Machined plates are a versatile and essential component in various industries, playing a crucial role in the manufacturing process and end-use applications. From the automotive and aerospace sectors to the medical and electronics industries, machined plates are utilized in a plethora of ways, showcasing their adaptability and functionality across different fields. In this article, we will explore the versatility of machined plates and their applications in various industries.

In the manufacturing industry, machined plates are used in a wide range of processes, including milling, drilling, and shaping of raw materials. These plates are often made from materials such as steel, aluminum, or titanium, and are precision-machined to meet the specific requirements of the manufacturing process. Whether it's for creating molds, fixtures, or tooling components, machined plates are crucial in ensuring the accuracy and quality of the final products.

The automotive industry also heavily relies on machined plates for the production of vehicles. These plates are used in the manufacturing of engine components, transmission systems, and chassis parts. The precision and durability of machined plates make them an ideal choice for meeting the stringent quality standards of the automotive sector. In addition, machined plates are also utilized in the maintenance and repair of vehicles, providing the necessary support for diagnostic equipment and machinery.

Moreover, the aerospace industry extensively utilizes machined plates for the production of aircraft parts and components. The lightweight yet robust properties of materials used in machined plates, such as aluminum and titanium, make them suitable for aerospace applications. Whether it's for fabricating structural components or intricate aerospace parts, machined plates play a critical role in ensuring the safety and reliability of aircraft.

Furthermore, the medical industry benefits from the versatility of machined plates, especially in the manufacturing of medical devices and equipment. From surgical instruments to prosthetic implants, machined plates are utilized in producing precise and complex medical components that meet stringent regulatory standards. The biocompatibility and precision of machined plates make them indispensable in the medical field, contributing to advancements in healthcare and patient outcomes.

In the electronics industry, machined plates are utilized in the production of electronic components and devices. The high precision and conductivity of materials used in machined plates make them essential for creating circuit boards, connectors, and other electronic parts. The ability of machined plates to meet tight tolerances and intricate specifications is crucial for ensuring the reliability and performance of electronic products.

In conclusion, machined plates play a crucial role in various industries, showcasing their adaptability and functionality in meeting the diverse needs of manufacturing and end-use applications. Whether it's for creating precision parts in the automotive and aerospace sectors, producing medical devices in the healthcare industry, or fabricating electronic components, machined plates continue to demonstrate their versatility and indispensability across different fields. As technology and innovation continue to advance, the applications of machined plates are expected to expand, further solidifying their role in driving progress and development across industries.

- Advantages and Limitations: Examining the Benefits and Challenges of Machined Plates in Different Applications

Machined plates have become a popular choice for a wide range of applications, from manufacturing to end-use. In this article, we will examine the advantages and limitations of using machined plates in different applications, shedding light on the benefits and challenges associated with this versatile material.

One of the main advantages of machined plates is their precision and consistency. Machining processes allow for tight tolerances and intricate designs, making machined plates ideal for applications that require high accuracy and reliability. This precision is particularly beneficial in manufacturing, where machined plates can be used to create complex components with minimal margin for error. Additionally, machined plates can be customized to meet specific requirements, making them a versatile solution for a variety of applications.

In addition to their precision, machined plates offer excellent strength and durability. This makes them suitable for heavy-duty applications, such as in the aerospace and automotive industries, where reliability is crucial. Machined plates are also resistant to wear and corrosion, making them a long-lasting option for applications that are exposed to harsh conditions.

Furthermore, machined plates have a sleek and professional appearance, making them a popular choice for end-use applications. From architectural features to consumer electronics, machined plates can enhance the aesthetics of products and structures, adding a touch of sophistication and quality.

Despite their many advantages, machined plates also have some limitations that should be considered. One of the main challenges is their cost, as the precision and customization offered by machined plates come at a higher price compared to other materials. Additionally, the process of machining plates can be time-consuming, which may not be practical for applications that require quick turnaround times.

Another limitation is the material itself, as machined plates are typically made from metals such as aluminum, steel, or titanium. While these materials offer excellent strength and durability, they can also be heavy and may not be suitable for applications that require lightweight solutions.

In conclusion, machined plates offer a myriad of advantages, including precision, strength, and a professional appearance. However, they also come with limitations such as cost and material constraints. By carefully considering these factors, engineers and designers can identify the most suitable applications for machined plates, maximizing their benefits and overcoming their challenges. Whether it’s in manufacturing or end-use applications, machined plates continue to prove their versatility and reliability in a wide range of industries.

- Future Trends: Anticipating the Evolution and Innovation of Machined Plates in Manufacturing and End-Use Applications

Machined plates have long been a staple in manufacturing and end-use applications, but as technology continues to evolve, so too does the versatility and potential of these essential components. In this article, we will explore the future trends surrounding machined plates, anticipating the evolution and innovation that will impact both the manufacturing and end-use applications across various industries.

One of the most significant trends in the evolution of machined plates is the advancement of materials and the processes used to manipulate them. Traditionally, machined plates were primarily made from metals such as steel or aluminum, but as new materials gain prominence, the possibilities for machined plates are expanding. Composite materials, for example, offer a lightweight yet durable alternative to traditional metals, opening up new opportunities for use in industries such as aerospace and automotive manufacturing.

In addition to the materials themselves, the processes used to machine plates are also evolving. Precision machining techniques, such as CNC milling and 3D printing, are becoming more advanced and accessible, allowing for greater intricacy and complexity in the design of machined plates. This opens the door for highly customized and specialized plates, tailored to meet the specific needs of individual applications.

Furthermore, the integration of digital technologies and automation is revolutionizing the manufacturing process, leading to greater efficiency and accuracy in the production of machined plates. The use of machine learning and artificial intelligence is enabling predictive maintenance and real-time monitoring of machined plate performance, minimizing downtime and optimizing overall production output.

Beyond manufacturing, the evolution of machined plates is also impacting end-use applications across a wide range of industries. In the medical field, for example, machined plates are used in orthopedic implants and surgical instruments. As the materials and manufacturing processes continue to advance, we can anticipate even greater customization and precision in the design and production of these critical medical components.

Similarly, in the electronics industry, the demand for smaller, lighter, and more durable components is driving innovation in machined plates. The ability to produce intricately designed and precisely machined plates is essential for the development of cutting-edge electronics, from smartphones to high-performance computers.

Overall, the future trends surrounding machined plates are poised to have a significant impact on both manufacturing and end-use applications. The evolution and innovation in materials, processes, and digital technologies are expanding the possibilities for machined plates, revolutionizing the way they are designed, produced, and utilized across a wide range of industries. As we look ahead, it is clear that machined plates will continue to play a crucial role in the advancement of technology and the development of innovative products.

Conclusion

In conclusion, the versatility of machined plates is truly remarkable, from their crucial role in the manufacturing process to their wide array of end-use applications. As a company with 18 years of experience in the industry, we have seen firsthand how machined plates have revolutionized the way products are manufactured and utilized in various industries. Their durability, precision, and adaptability make them an indispensable component in countless applications, and the potential for their use continues to grow. The future of machined plates is indeed promising, and we are excited to continue exploring and harnessing their potential for the benefit of our clients and the industries we serve.