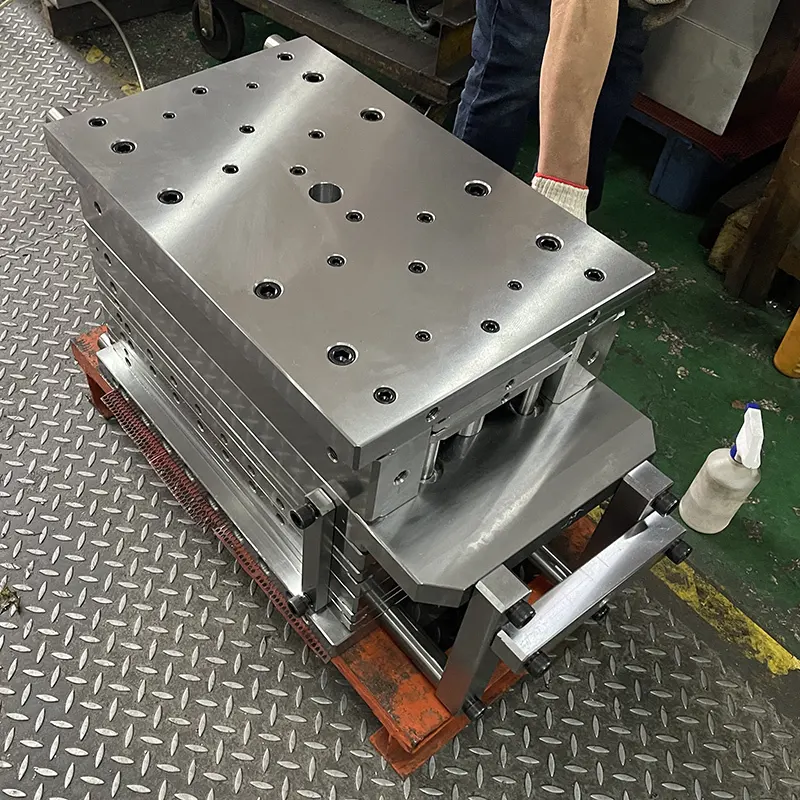

Best Mould Base for Industrial

Company Advantages

· Owing to the years of industrial experience, Ruifengda mould base is elaborately manufactured in an accurate and effective way.

· The rigorous quality checking process guarantees customers a full range of quality product.

· Ruifengda Brand's operating business awareness has continued to rise.

|

Tolerance |

0.02mm-0.005mm |

Rust prevention measures |

Anti rust oil, anti rust spray, vacuum packaging... |

|

Mould life |

300000-500000 Shots |

Transaction mode |

FOB/CIF |

|

Major equipment |

YASDA, OKUMA |

Testing |

CMM, Opening and closing activities... |

|

Size |

Customer Size Accepted |

Runner |

Hot runner |

|

Minimum order quantity |

1 Set |

Supply ability |

300-400 sets per month |

|

Material Science |

S50C, P20, 1.2311, 718H, 4Cr13H, 420H, S136H ... |

Payment method |

T/T, Paypal, Cash |

|

Packing |

Wooden box, plastic film |

OEM |

Available |

Accessories

We offer a comprehensive range of accessories for mould bases, tailored to your specific requirements. Our offerings include both standard and nonstandard accessories from reputable brands such as HASCO, MISUMI, PUNCH, DME, and LKM. Additionally, we have the capability to manufacture custom accessories such as bronze components, ball cage bushes, and self-lubricating parts.

Cavity and core plates

The parallelism and verticality of pocket should be controlled within 0.02mm. The length, width, and depth tolerance of the precision mould base should be 0~+0.02mm, and the thickness tolerance of the main plates should be ± 0.02mm. Precision machining is required for screw holes, water line holes, ejector pin holes, nozzle holes, etc. All surfaces should be scratch free, bright and flat, all chamfers should comply with our company's standards and should be uniform. In the actual machining process, corresponding precision requirements will be formulated based on specific mold design and customer needs.

process, precise measurements and strict adherence to the design specifications are crucial to ensure the accurate and high-quality production of the mold. Any deviation from the precision requirements could result in defective molds and impact the overall production process. Therefore, it is imperative to strictly adhere to the precision requirements and meticulously inspect the quality of the mold throughout the manufacturing process.

Runner plate

After processing, we conduct strict CMM testing on the hole spacing. This ensures that the dimensional accuracy of the cavities is maintained, and any variations are identified and corrected. Additionally, we pay close attention to the alignment of the cavities to ensure that they are perfectly parallel and perpendicular to the mold base. This is crucial for the proper functioning of the mold and for achieving consistent and high-quality finished products. The meticulous attention to detail in the aperture and spacing of cavities is essential in the production of precision molds that meet the exacting requirements of our customers. Our thorough quality control measures guarantee the reliability and performance of the molds we manufacture.

Testing

We use CMM coordinate measurement and generate accurate measurement reports. Its high-precision measurement results can ensure product quality and tolerance requirements. The data collected from the CMM is also used for process control and improvement, allowing us to make necessary adjustments to meet customer specifications. Our skilled technicians are trained to operate the CMM effectively, ensuring consistency and reliability in our measurements. Additionally, the CMM helps us identify any potential issues early in the production process, reducing the likelihood of costly rework or product defects. Overall, the use of CMM technology plays a crucial role in our commitment to delivering high-quality products to our customers.

Anti-corrosion treatment

In order to reduce the impact of rust on mould base during shipping, we will use anti rust spray and anti rust oil on the surface of mould base, and then wrap them with plastic film. If necessary, vacuum packaging will be used.

fAQ

Company Features

· Ruifengda Brand has developed mould base under the growing needs and is now gaining more and more achievements for it.

· Our factory is fully equipped. It helps us with flexible product design as well as production in prototypes or large and medium orders. Our factory is fully equipped. We continue to invest heavily in the latest equipment, such as high-speed equipment, to ensure satisfactory quality, capacity, time to market and cost.

· Our mission is to make every customer enjoy shopping in Ruifengda Brand. Inquire now!

Application of the Product

The mould base produced by our company is widely used in various industries and fields.

Our solutions are developed by understanding the customer's situation and combining the current market conditions. Therefore, they are all targeted and can effectively solve problems of customers.

Product Comparison

mould base has the following advantages over other products in the same category.

Enterprise Advantages

Ruifengda has an experienced and excellent team, whose team members are equipped with great R&D capabilities and advanced production technology.

Following the service concept of 'all customer-centric', our company is dedicated to providing customers with high-quality products and professional services.

Our company adheres to the core values of 'passion, dedication, integrity, innovation and development'. And we regard 'quality first, customer first, people-oriented' as our business philosophy. With science and technology as the guide, we create a first-class brand in the industry based on technology and management advantages. Moreover, we constantly provide quality products and services for customer.

Ruifengda was founded in After years of exploration and development, our company's scale has been continuously expanded and the strength has been constantly enhanced.

Based on the domestic market, Ruifengda is actively exploring foreign markets.