Understanding The Importance Of A Quality Car Mold Base For Manufacturing

Are you looking to improve the quality and efficiency of your car manufacturing process? Look no further! Understanding the importance of a quality car mold base is crucial for ensuring top-notch production. In this article, we will delve into the significance of a quality car mold base and how it can significantly impact the overall manufacturing process. Whether you are a car manufacturer, a supplier, or simply interested in the automotive industry, this article will provide valuable insights into the importance of investing in a high-quality car mold base. So, sit back, relax, and let us take you on a journey to understanding the crucial role of a quality car mold base in manufacturing.

- The Role of Car Mold Bases in Manufacturing

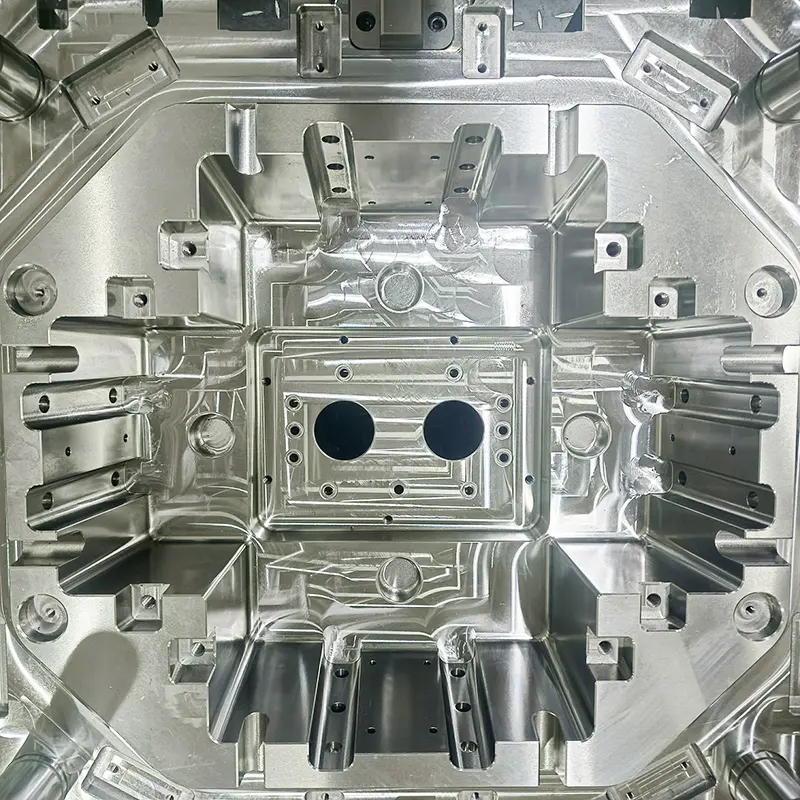

The car mold base plays a vital role in the manufacturing process of automotive parts. It serves as the foundation for creating the molds used to produce various components of a car, including body panels, interior features, and other structural elements. A quality car mold base is essential for ensuring the accuracy, precision, and consistency of the parts being produced, ultimately impacting the overall quality of the vehicle.

One of the key functions of a car mold base is to provide a stable and reliable platform for the mold to be mounted. This is important because any movement or instability in the mold base can result in imperfections or defects in the final product. A high-quality mold base is designed to withstand the pressure, heat, and force exerted during the molding process, ensuring that the mold remains in place and the resulting parts are consistent and free of defects.

In addition, the design and construction of the mold base play a crucial role in determining the efficiency and performance of the manufacturing process. A well-designed mold base will incorporate features such as cooling channels, ejection systems, and other components that are essential for the production of high-quality parts. By integrating these elements into the mold base, manufacturers can optimize the production process, reduce cycle times, and improve overall productivity.

Furthermore, the material used in the construction of the mold base is a critical factor in ensuring its quality and durability. The mold base needs to be made from a material that can withstand the rigors of the molding process, including high temperatures, pressure, and wear. Common materials used for car mold bases include steel, aluminum, and various grades of tool steel, each offering its own unique set of properties and benefits.

When it comes to manufacturing automotive parts, precision and accuracy are paramount. The quality of the mold base directly impacts the dimensional accuracy and surface finish of the final parts. A well-constructed mold base, combined with precise machining and finishing processes, ensures that the parts produced meet the required specifications and standards.

Another important aspect of car mold bases is their role in facilitating design and engineering changes. As automotive technology advances and product designs evolve, the ability to modify and adapt molds becomes crucial. A high-quality mold base allows for easy and efficient modifications, enabling manufacturers to quickly implement changes and improvements in the production process without compromising quality or efficiency.

In conclusion, the role of a quality car mold base in manufacturing cannot be overstated. It is a critical component in the production of automotive parts, impacting the quality, precision, and efficiency of the manufacturing process. Manufacturers must prioritize the selection of high-quality mold bases to ensure the consistent production of high-quality parts that meet the stringent requirements of the automotive industry.

- How Quality Car Mold Bases Impact Production

Car mold bases are a crucial component in the manufacturing process of automotive parts, as they directly impact the production quality and efficiency of the final product. This article aims to shed light on the significance of using high-quality car mold bases in the manufacturing industry and how they can significantly impact production.

First and foremost, a quality car mold base plays a pivotal role in ensuring the precision and accuracy of the automotive parts being produced. The mold base serves as the foundation for creating the mold cavity, which ultimately determines the shape and dimensions of the final product. Therefore, any imperfections or inaccuracies in the mold base can lead to defects in the parts, resulting in wasted materials and time. By using a high-quality car mold base, manufacturers can minimize the risk of discrepancies and inconsistencies in their production process, ultimately leading to superior part quality.

Furthermore, the durability and longevity of a car mold base are critical factors that can impact production. A well-built mold base is designed to withstand the wear and tear of repeated use, ensuring that it maintains its structural integrity over time. This is particularly important in high-volume production settings, where the mold base is subjected to constant use and may be prone to damage or deformation. By investing in a quality car mold base, manufacturers can increase the lifespan of their molds, reduce the need for frequent replacements, and minimize downtime in their production processes.

In addition to precision and durability, the design and construction of a car mold base can also influence the efficiency of production. A well-designed mold base allows for easy and quick setup, ensuring that the production process is streamlined and optimized for maximum productivity. This is especially beneficial for manufacturers who need to produce a large volume of automotive parts within a limited timeframe. By using a quality mold base, they can eliminate potential bottlenecks and inefficiencies in their production line, ultimately leading to cost savings and improved lead times.

Moreover, the choice of material for the car mold base can significantly impact its performance and overall production quality. High-quality materials, such as tool steel or aluminum, offer superior strength, thermal conductivity, and corrosion resistance, making them ideal for withstanding the demands of automotive part manufacturing. Additionally, the use of advanced manufacturing techniques, such as CNC machining, can further enhance the precision and consistency of the mold base, ensuring that the final product meets the highest quality standards.

In conclusion, it is evident that the use of a quality car mold base is paramount in the manufacturing industry, particularly in the production of automotive parts. By prioritizing precision, durability, efficiency, and material quality, manufacturers can significantly improve their production processes and ultimately deliver superior products to their customers. As such, investing in high-quality car mold bases is not only essential for maintaining a competitive edge in the market but also for ensuring the overall success and sustainability of the manufacturing operations.

- Factors to Consider When Selecting a Car Mold Base

When it comes to manufacturing car parts, the quality of the car mold base is a crucial factor to consider. The car mold base serves as the foundation for creating the molds used in the manufacturing of car parts, and the quality of the mold base can directly impact the quality and efficiency of the manufacturing process. In order to select the best car mold base for manufacturing, there are several important factors that must be taken into consideration.

The first factor to consider when selecting a car mold base is the material from which it is made. The material used to construct the mold base should be durable, able to withstand high temperatures and pressure, and resistant to wear and tear. Common materials used for car mold bases include steel, aluminum, and various alloys. Each of these materials has its own unique properties and advantages, and the choice of material will depend on the specific requirements of the manufacturing process.

Another important factor to consider when selecting a car mold base is the size and shape of the base. The mold base must be designed to accommodate the specific dimensions and configuration of the car parts being manufactured. It is crucial that the mold base provides a precise and accurate fit for the molds, in order to ensure the quality and consistency of the finished car parts. Additionally, the mold base should be designed to allow for easy and efficient assembly and disassembly of the molds, in order to streamline the manufacturing process.

In addition to the material and size of the mold base, it is also important to consider the precision and quality of the manufacturing process used to produce the mold base. The mold base should be machined to exacting specifications, with tight tolerances and smooth surfaces. Any imperfections or inconsistencies in the mold base can result in defects or irregularities in the finished car parts, so it is essential that the mold base is manufactured with the highest level of precision and quality.

Furthermore, it is important to consider the cost and lead time associated with the production of the mold base. While it is important to prioritize quality and precision, it is also necessary to consider the overall cost and time frame for producing the mold base. The choice of material, manufacturing process, and supplier for the mold base will all impact its cost and lead time, so it is important to carefully weigh these factors in relation to the specific requirements of the manufacturing process.

In conclusion, the selection of a car mold base is a critical decision that can significantly impact the quality and efficiency of the manufacturing process for car parts. By carefully considering the material, size, precision, and cost of the mold base, manufacturers can ensure that they select the best mold base for their specific needs. Ultimately, investing in a high-quality car mold base is essential for achieving consistent, high-quality car parts in the manufacturing process.

- The Importance of Precision and Durability in Car Mold Bases

A car mold base is an essential component in the manufacturing process of automotive parts. It serves as the foundation for creating molds that will be used to produce various car parts such as bumpers, trims, panels, and other exterior components. The importance of precision and durability in car mold bases cannot be overstated, as they directly impact the quality and consistency of the final products. Manufacturers rely on the reliability and longevity of these mold bases to ensure the production of high-quality car parts.

Precision is a critical aspect of car mold bases, as it determines the accuracy and consistency of the final products. The dimensions and specifications of the molds must be precise to ensure that the car parts are manufactured to the exact specifications required. Even the slightest deviation from the intended measurements can result in defective parts and costly rework. Therefore, a high level of precision in car mold bases is crucial for meeting the stringent quality standards and specifications set by automotive manufacturers.

Durability is another key consideration when it comes to car mold bases. The manufacturing process involves high pressure, temperature, and repeated use of the molds, which can subject them to significant wear and tear. A durable mold base is essential to withstand the rigors of the manufacturing process and maintain its precision and integrity over time. It should be able to withstand the demands of high-volume production without compromising on quality.

When choosing a car mold base, manufacturers should prioritize materials that offer both precision and durability. High-quality steel, aluminum, and composite materials are commonly used for mold bases due to their strength, stability, and resistance to wear. These materials are capable of maintaining the required precision and tolerances, ensuring the consistent production of high-quality car parts. Additionally, the use of advanced technologies such as CNC machining and precision grinding further enhances the accuracy and reliability of car mold bases.

The importance of precision and durability in car mold bases extends beyond the manufacturing process. It directly impacts the overall cost-effectiveness and efficiency of car part production. A precise mold base minimizes the need for rework and reduces the risk of producing defective parts, ultimately saving time and resources. On the other hand, a durable mold base prolongs the lifespan of the molds, reducing the frequency of replacements and maintenance, thereby improving the overall production efficiency.

In conclusion, the importance of a quality car mold base for manufacturing cannot be emphasized enough. Precision and durability are essential attributes that directly influence the quality, consistency, and cost-effectiveness of producing car parts. By prioritizing these characteristics in the selection of mold bases, manufacturers can ensure the reliability and longevity of their molds, ultimately leading to the production of high-quality car parts that meet the stringent standards of the automotive industry.

- Advantages of Investing in High-Quality Car Mold Bases

When it comes to manufacturing high-quality automobiles, the importance of using a quality car mold base cannot be overstated. The car mold base is the foundation on which the entire manufacturing process is built, and investing in a high-quality mold base can yield a wide range of advantages for car manufacturers. In this article, we will explore the various advantages of investing in high-quality car mold bases, and why they are essential for the production of top-notch automobiles.

One of the primary advantages of using a high-quality car mold base is the precision and accuracy it offers. A quality mold base is manufactured to exacting standards, ensuring that the resulting car parts are consistently precise and uniform. This level of precision is crucial for producing high-quality automobiles that meet the strict standards of the automotive industry. Whether it's the body panels, interior components, or engine parts, a high-quality mold base ensures that every piece is manufactured to the same exacting specifications.

In addition to precision, high-quality car mold bases also offer superior durability and longevity. These mold bases are typically constructed from top-grade materials, such as high-strength steel, that are engineered to withstand the rigors of the manufacturing process. This means that the mold base can be used repeatedly without suffering from wear and tear, resulting in cost savings and increased productivity for car manufacturers. Furthermore, the durability of a quality mold base ensures that the resulting car parts are robust and long-lasting, contributing to the overall reliability and longevity of the finished automobiles.

Furthermore, investing in high-quality car mold bases can also lead to improved efficiency and cost-effectiveness in the manufacturing process. When using a quality mold base, manufacturers can expect reduced downtime due to maintenance and repairs, as well as decreased material waste from faulty or inconsistent parts. This translates to increased efficiency and productivity, ultimately resulting in cost savings for the manufacturer. Additionally, the consistent precision and quality of the parts produced from a high-quality mold base can also reduce the need for post-production modifications and adjustments, further streamlining the manufacturing process.

Another advantage of using high-quality car mold bases is the potential for customization and flexibility. These mold bases are often designed with versatility in mind, allowing for easy adaptation to accommodate changes in design or production requirements. This flexibility can be invaluable in the constantly evolving automotive industry, where the ability to quickly adapt to new technologies, designs, and customer preferences is essential for success. With a high-quality mold base, manufacturers can more easily and cost-effectively make adjustments or improvements to their production processes, ensuring that they stay competitive in the market.

In conclusion, investing in high-quality car mold bases is crucial for car manufacturers looking to produce top-quality automobiles efficiently and cost-effectively. The precision, durability, efficiency, and flexibility offered by these mold bases can have a significant impact on the overall success of a manufacturing operation. By prioritizing the use of high-quality mold bases, car manufacturers can ensure that their production processes are optimized for excellence, leading to superior vehicles that meet the high standards of the automotive industry.

Conclusion

In conclusion, it is clear that a quality car mold base is crucial for successful manufacturing in the automotive industry. With 18 years of experience, our company understands the importance of precision, durability, and reliability in producing high-quality molded car parts. By investing in a quality car mold base, manufacturers can ensure that their products meet the highest standards and exceed customer expectations. Ultimately, choosing the right mold base is a significant factor in the success and efficiency of the manufacturing process. As we continue to grow and evolve in the industry, we remain committed to delivering top-notch mold bases that contribute to the production of exceptional car parts. Thank you for reading and we look forward to continuing to serve the automotive manufacturing sector with our expertise and dedication to quality.