The Importance Of A Quality Car Mould Base For Manufacturing

Are you looking to improve the efficiency and precision of your car manufacturing process? Look no further than the importance of a quality car mould base. In this article, we will explore how investing in a quality mould base can significantly enhance the manufacturing process, leading to higher quality products and increased productivity. Read on to discover the numerous benefits of prioritizing a top-notch car mould base in your manufacturing operations.

- Understanding the Role of Car Mould Bases in Manufacturing

.

Understanding the Role of Car Mould Bases in Manufacturing

When it comes to manufacturing cars, one of the most important aspects of the process is the use of high-quality car mould bases. These bases are crucial in ensuring that the vehicles produced are of a top-notch standard and meet all the necessary requirements for safety, durability, and performance. In this article, we will delve into the importance of a quality car mould base for manufacturing and explore its role in the production of automobiles.

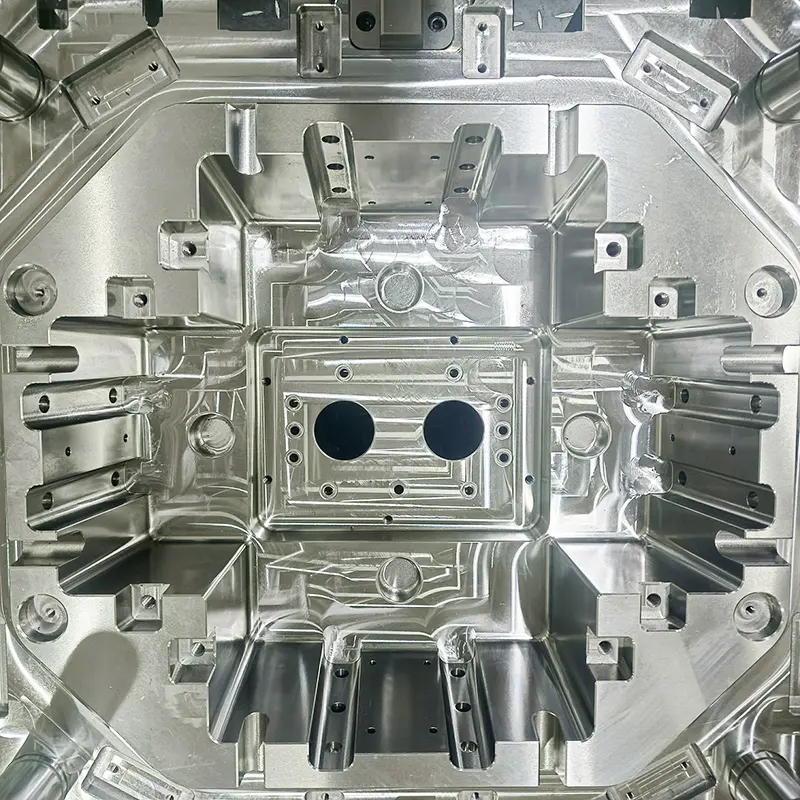

To begin, it is essential to understand what exactly a car mould base is and how it is used in the manufacturing process. A car mould base is essentially a framework or structure upon which the various components of a car are built. It serves as the foundation for the entire vehicle and provides a stable and reliable platform for the assembly of different parts. In essence, without a quality car mould base, it would be virtually impossible to manufacture a car that meets the necessary standards and specifications.

The role of a car mould base in manufacturing is multi-faceted and encompasses several key aspects that are critical to the production of high-quality automobiles. One of the primary functions of a car mould base is to provide the necessary support and stability for the various components of the vehicle. This is essential in ensuring that the parts fit together seamlessly and that the final product is structurally sound and reliable.

Moreover, a quality car mould base also plays a significant role in facilitating the assembly process. By providing a solid foundation for the different components, the mould base allows for efficient and precise assembly, thereby reducing the likelihood of errors or defects in the finished product. This is crucial in ensuring that the vehicles produced are of a consistently high standard and meet the stringent quality control measures that are paramount in the automotive industry.

Furthermore, car mould bases are also instrumental in enabling the production of vehicles that are not only safe and reliable but also aesthetically pleasing. The precise and accurate construction of the mould base allows for the creation of perfectly symmetrical and uniform components, resulting in a car that is visually appealing and exudes quality craftsmanship. This is essential in today's competitive market, where consumers place a high value on the overall design and appearance of the vehicles they purchase.

In addition to these key functions, a quality car mould base also contributes to the overall efficiency and cost-effectiveness of the manufacturing process. By providing a stable and reliable platform for the assembly of components, the mould base helps to streamline production and reduce the likelihood of errors or rework, ultimately saving time and resources. This is crucial in ensuring that the manufacturing process is as efficient and profitable as possible, which is essential for the success of any automotive company.

In conclusion, the importance of a quality car mould base for manufacturing cannot be overstated. From providing support and stability for the various components to facilitating efficient assembly and ensuring the production of safe, reliable, and visually appealing vehicles, the role of a car mould base is indispensable in the automotive industry. Therefore, it is crucial for car manufacturers to invest in high-quality mould bases to ensure the production of top-notch automobiles that meet the high standards of today's market.

- Factors to Consider When Choosing a Quality Car Mould Base

When it comes to manufacturing, the quality of the mould base plays a crucial role in the production of high-quality automotive components. The car mould base is the foundation of the moulding process, and its quality directly impacts the overall quality, precision, and efficiency of the manufacturing process.

Factors to Consider When Choosing a Quality Car Mould Base

1. Material Quality:

The material used for the car mould base is one of the most critical factors to consider. It should be made from high-quality and durable materials that can withstand the high pressure and temperature of the moulding process. Generally, the most commonly used materials for car mould bases are steel, aluminum, and zinc alloys. Steel is commonly used for its durability and high resistance to wear and tear, while aluminum and zinc alloys are known for their light weight and corrosion resistance.

2. Precision and Tolerance:

The precision and tolerance of the car mould base are essential for producing accurate and consistent automotive components. When choosing a quality car mould base, it is crucial to consider factors such as the dimensional accuracy, surface finish, and flatness. The mould base should be manufactured with tight tolerances to ensure that the moulded parts are uniform and free from defects.

3. Design and Configuration:

The design and configuration of the car mould base are also crucial factors to consider. It should be designed to accommodate the specific requirements of the automotive components to be manufactured. The design should allow for easy access to the mould cavity, proper cooling and ejection systems, and the integration of any necessary components such as slides, lifters, and inserts.

4. Heat Treatment:

The heat treatment of the car mould base is another important consideration. Proper heat treatment can significantly increase the hardness and wear resistance of the mould base, resulting in a longer lifespan and improved performance. It is essential to choose a car mould base that has been subjected to the appropriate heat treatment process to ensure its durability and reliability.

5. Longevity and Maintenance:

The longevity and maintenance of the car mould base are critical for the overall cost-effectiveness of the manufacturing process. A quality mould base should be designed for long-term use, with minimal maintenance requirements. It should be resistant to wear and corrosion, and easy to clean and maintain, which will reduce downtime and increase the efficiency of the manufacturing process.

In conclusion, the selection of a quality car mould base is essential for ensuring the production of high-quality automotive components. When choosing a car mould base, it is crucial to consider factors such as material quality, precision and tolerance, design and configuration, heat treatment, and longevity and maintenance. By carefully considering these factors, manufacturers can ensure the reliability, precision, and efficiency of their manufacturing processes, leading to superior automotive components that meet the highest standards of quality and performance.

- Impact of Quality Car Mould Bases on Manufacturing Efficiency

The Importance of a Quality Car Mould Base for Manufacturing - Impact of Quality Car Mould Bases on Manufacturing Efficiency

A car mould base is a crucial component in the manufacturing process of automotive parts. It serves as the foundation for creating moulds that will ultimately be used to produce car parts such as body panels, interior components, and other critical elements. The quality of the car mould base has a significant impact on the overall manufacturing efficiency, as it can affect the precision, durability, and consistency of the moulds it produces.

When it comes to manufacturing automotive parts, precision is key. Any deviation from the intended design specifications can result in parts that do not fit properly, compromising the safety and performance of the vehicle. Therefore, the quality of the car mould base is paramount in ensuring that the moulds it produces are accurate and meet the required standards. A well-constructed mould base will provide the necessary stability and precision, leading to high-quality parts that meet the strict requirements of the automotive industry.

In addition to precision, the durability of the car mould base is also essential. The manufacturing of automotive parts often involves high pressures, temperatures, and repetitive cycles. A low-quality mould base may not be able to withstand these conditions, resulting in deformation, wear, and tear over time. This can lead to increased downtime for maintenance and repairs, as well as additional costs for replacement parts. On the other hand, a high-quality car mould base will be able to endure the rigors of the manufacturing process, providing longevity and reliability.

Consistency is another critical factor in manufacturing efficiency. A quality car mould base will ensure that the moulds it produces are consistent in their dimensions and properties. This is crucial for mass production, as any variations can lead to rejects and rework, thereby slowing down the manufacturing process and increasing costs. By investing in a high-quality car mould base, manufacturers can achieve a higher level of consistency in their production, leading to improved efficiency and reduced waste.

Furthermore, the design of the car mould base can also impact manufacturing efficiency. A well-designed mould base can optimize the manufacturing process by reducing setup times, minimizing material waste, and improving cycle times. For example, a modular mould base design can allow for quick changeovers and flexibility in production, enabling manufacturers to respond to changing demands and reduce lead times.

In conclusion, the impact of quality car mould bases on manufacturing efficiency cannot be overstated. Precision, durability, consistency, and design are all key factors that contribute to the overall efficiency of the manufacturing process. By investing in high-quality car mould bases, manufacturers can ensure that they produce high-quality automotive parts consistently, efficiently, and cost-effectively. Ultimately, this will enable them to stay competitive in the fast-paced and demanding automotive industry.

- The Importance of Precision and Durability in Car Mould Bases

Car mould bases are an essential component in the manufacturing of automotive parts. They provide the foundation for creating precise and durable moulds that are used to produce various car components. The importance of precision and durability in car mould bases cannot be overstated, as they directly impact the quality and efficiency of the manufacturing process.

Precision is crucial in car mould bases, as it ensures that the moulds produced are accurate and consistent. A high level of precision is necessary to create car components that fit together seamlessly and function as intended. Any deviation from the desired specifications can result in costly errors and rework, leading to delays in production and increased expenses. Therefore, car mould bases must be designed and manufactured with meticulous attention to detail to achieve the necessary precision.

Durability is equally important in car mould bases, as they are subjected to high levels of stress and pressure during the manufacturing process. The materials used in constructing the mould bases must be able to withstand the rigors of repeated use without succumbing to wear and tear. Additionally, the design and construction of the mould bases must be able to maintain their structural integrity and dimensional stability over time. This ensures that the moulds produced remain consistent and accurate throughout their lifespan, contributing to the overall quality of the car components.

When it comes to precision, the design and construction of car mould bases must take into account the specific requirements of the automotive industry. The tolerances for car components are often very tight, requiring the mould bases to be manufactured with exacting precision. This means that the dimensions and geometries of the mould bases must be meticulously controlled to ensure that the resulting moulds meet the required specifications. Additionally, the surfaces of the mould bases must be carefully finished to minimize any imperfections that could affect the quality of the moulds produced.

In terms of durability, the materials used in car mould bases play a critical role in their long-term performance. The mould bases must be made from high-quality, durable materials that can withstand the demands of the manufacturing process. This often involves the use of high-strength metals or alloys that can maintain their integrity under the conditions of high pressure and temperature. Furthermore, the construction of the mould bases must be carefully engineered to ensure that they can endure the stresses of repeated use without succumbing to fatigue or deformation.

In conclusion, the importance of precision and durability in car mould bases cannot be overstated. These qualities directly impact the quality and efficiency of the manufacturing process for automotive components. By prioritizing precision and durability in the design and construction of car mould bases, manufacturers can ensure the consistent production of high-quality car parts that meet the stringent demands of the automotive industry. Ultimately, this leads to improved reliability and performance in the finished vehicles, benefiting both manufacturers and consumers alike.

- Advantages of Investing in High-Quality Car Mould Bases for Manufacturing Operations

Investing in high-quality car mould bases is crucial for any manufacturing operation in the automotive industry. These mould bases serve as the foundation for producing various car parts and components, and the quality of these bases can significantly impact the overall manufacturing process. In this article, we will explore the importance of using high-quality car mould bases for manufacturing and discuss the advantages they offer to businesses in the automotive sector.

First and foremost, high-quality car mould bases are essential for ensuring the accuracy and precision of the produced parts. The design and dimensions of car mould bases directly influence the quality and consistency of the parts manufactured using these moulds. With low-quality mould bases, there is a higher risk of dimensional inaccuracies and variations in the parts, which can lead to defects and inefficiencies in the production process. On the other hand, investing in high-quality mould bases ensures that the parts produced are consistent in size, shape, and overall quality, meeting the required standards and specifications.

Another advantage of investing in high-quality car mould bases is their durability and longevity. High-quality mould bases are typically made from top-grade materials and undergo rigorous manufacturing processes to withstand the wear and tear of continuous use. This longevity not only minimizes the need for frequent replacements but also contributes to overall cost savings for the manufacturing operation. Additionally, the durability of high-quality mould bases ensures that the produced parts maintain their integrity and quality over time, resulting in greater customer satisfaction and trust in the brand's products.

Furthermore, high-quality car mould bases can enhance the efficiency and productivity of the manufacturing process. With precise and reliable mould bases, there is a reduction in the occurrence of errors and rejections, leading to improved throughput and lower production costs. The consistent quality and accuracy of the parts also contribute to smoother assembly processes and reduced rework, ultimately resulting in higher output and increased operational efficiency. This efficiency not only benefits the manufacturing operation but also enhances the overall competitiveness and reputation of the business in the automotive industry.

In addition to the technical advantages, investing in high-quality car mould bases can also have a positive impact on the overall manufacturing environment. Reliable and well-built mould bases contribute to a safer and more stable production process, reducing the likelihood of accidents and downtime. This creates a more conducive and organized work environment, promoting employee morale and well-being. Moreover, high-quality mould bases can facilitate the implementation of advanced manufacturing technologies and processes, enabling the business to stay ahead in the rapidly evolving automotive industry.

In conclusion, the importance of investing in high-quality car mould bases for manufacturing in the automotive industry cannot be overstated. These mould bases play a critical role in ensuring the accuracy, consistency, durability, and efficiency of the production process, ultimately contributing to the success and competitiveness of the business. By prioritizing the use of high-quality mould bases, automotive manufacturers can achieve superior results, meet industry standards, and satisfy customer expectations, ultimately leading to sustainable growth and success.

Conclusion

In conclusion, it is evident that the quality of a car mould base plays a crucial role in the manufacturing process. With 18 years of experience in the industry, our company understands the importance of investing in a high-quality mould base to ensure precise and efficient production. From achieving accurate dimensions to ensuring durability and longevity, a quality car mould base is essential for delivering superior end products. By prioritizing the use of a top-notch mould base, manufacturers can improve their production processes, reduce costs, and ultimately enhance the overall quality of their vehicles. As we continue to innovate and refine our manufacturing techniques, we remain committed to upholding the highest standards in car mould base quality to meet the evolving needs of the automotive industry. With an unwavering dedication to excellence, we recognize the indispensable role of a quality mould base for manufacturing and strive to exceed expectations in delivering top-of-the-line solutions for our clients.